Explore graphite ore processing line on Terbaik Machinery. Discover industry-leading solutions for graphite beneficiation and processing. Learn about our advanced mineral processing equipment tailored for graphite production. Choose Terbaik Machinery for efficient and reliable graphite ore processing.

Graphite mines primarily involve flake graphite and microcrystalline graphite, with flotation being the predominant beneficiation method. Here's an overview of the flotation process and the equipment typically used:

1. Flotation Agents:

Commonly used flotation agents include kerosene, No. 2 oil, water glass, lime, etc.

Graphite's good buoyancy makes it suitable for flotation.

2. Ore Preparation:

Due to graphite's inlaying nature, it is typically ground to a coarse fineness, with 45-60% passing through 100 mesh.

3. Flake Graphite Flotation Process:

Rough Grinding and Rough Sorting: Initial processing involves rough grinding and sorting to obtain low-grade concentrates (40-50% grade), primarily composed of contiguous bodies.

Re-grinding and Re-election: Low-grade fines are re-ground and re-floated multiple times (3-7 times, typically 3-4 times) to achieve final concentrate grades of 85-89%. This process inhibits symbiotic minerals like pyrite and mica and may involve the addition of agents like lime, starch, and water glass.

Graphite Ore Types

1. Earthy Graphite (Aphanitic Graphite):

Features small, earthy crystals with a dull appearance.

Typically has high raw ore grades (60-80%), but poor flotation ability.

Ores below 65% grade are generally not mined, while those between 65% and 80% can be used after sorting.

2. Flake Graphite:

Appears as scales or leaves with lower raw ore grades (3-5%, up to 20-25%).

Boasts excellent flotation ability, allowing grade enhancement to over 90% post-flotation.

Preferred for manufacturing high-grade carbon products due to superior properties.

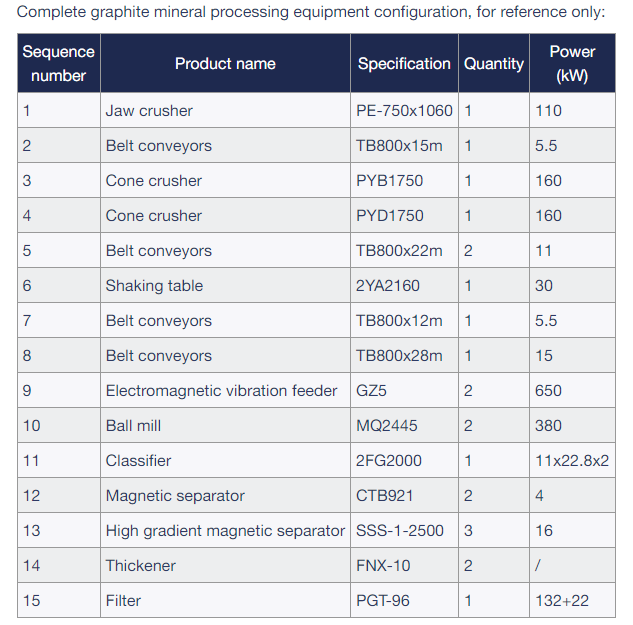

High-End Equipment Configuration:

The graphite ore processing line features high-end equipment with a compact and rational layout, occupying minimal floor space and significantly reducing civil construction costs.

High Automation Level:

This production line boasts high automation, allowing remote control via computer. This lowers investment costs in terms of labor and materials.

Safe and Stable Operation:

Operations are safe and stable, with an exceptionally low failure rate that reduces maintenance costs. It operates without generating dust or noise, ensuring no environmental harm.

Increased Concentrate Grade:

By enhancing the concentrate grade by 10%, the industrial value of graphite mineral materials is substantially elevated. Moreover, the comprehensive recovery rate is significantly enhanced.

The graphite ore beneficiation equipment is equipped with high-end, compact, and logically arranged machinery, occupying minimal land and minimizing civil construction costs. This production line achieves a high level of automation, enabling remote computer control and reducing human and material investment costs. It operates with utmost safety and stability, boasting an exceptionally low failure rate that minimizes maintenance expenses. There are no dust emissions or noise pollution, ensuring environmental friendliness. Furthermore, it enhances the concentrate grade by ten percentage points, thereby greatly enhancing the industrial value of graphite mineral materials and achieving a markedly improved total recovery rate.

Convenient transportation, crawler walking, no damage to the road, equipped with multi-functional accessories, Drived by oil and electricity.

The whole crushing plant adopts all-wheel drive to realize rotating direction in place, with perfect protection function, especially suitable for narrow and complex site.

The crawler crushing plant could be optional for jaw crusher, impatct crusher, cone crusher, VSI crusher etc.

1. Amorphous Graphite Ore:

Process: Includes coarse crushing, medium crushing, fine crushing, grinding, flotation, dehydration, drying, and classification.

Equipment: Utilizes jaw crushers for primary crushing, hydraulic cone crushers and hammer crushers for medium and fine crushing, ball mills for grinding, SF-type and XJK-type flotation machines, dehydration screens, centrifugal dehydrators, spiral classifiers, and dryers.

2. Crystal Graphite Ore:

Process: Involves simpler crushing due to medium to soft nature and grade (2% to 10%).

Crushing Options: Includes three-stage open circuit, two-stage open circuit, or single-stage crushing; some smaller mines process weathered ores directly in ball mills.

Flotation: Typically follows closed-circuit approach with multi-stage grinding and beneficiation, aiming for recovery rates around 80%.

3. Cryptocrystalline Graphite Ore:

Process: Uses flotation as the primary method due to favorable flotation performance of scale graphite.

Additional Methods: May involve electrical separation, gravity separation, and others to achieve effective separation and recovery.

1. Ball Mill:

Function: Key equipment for crushing after material breakage, used in cement, silicate products, new building materials, refractories, fertilizers, black and non-ferrous metal beneficiation, and glass-ceramic industries.

Operation: Performs dry or wet grinding of various ores and abrasive materials, crucial in mineral processing, construction, and chemical industries.

2. Flotation Machines:

Non-ferrous Metals: Copper, lead, zinc, gold, silver, platinum, tungsten, molybdenum, tantalum, lithium, uranium.

Ferrous Metals: Iron ore, titanium ore, manganese ore, vanadium ore.

Non-Metallic Minerals: Used in flotation beneficiation processes.

Function: Enables separation based on specific material properties, essential for processing special substances like electrolytic aluminum.

This overview highlights the specialized methods and equipment integral to maximizing ore recovery and ensuring high-quality products in graphite mining operations, reflecting the diverse needs and technical requirements of different ore types.

*The output will vary according to different materials, feed particle size and other factors