Terbaikmachinery offers top-of-the-line gold leaching tanks designed for efficient extraction processes. Our gold leaching equipment, including cyanide leaching tanks, is engineered to optimize gold recovery in mineral processing operations. Trust Terbaikmachinery for expertly crafted leaching solutions that ensure high performance and enhance productivity in your gold extraction processes.

Unlock the Full Potential of Your Mining Operations with Our Advanced Gold Leaching Tanks

Are you looking to optimize your gold extraction process? Look no further! Our high-efficiency Gold Leaching Tanks are designed to maximize the recovery of gold from your ore, ensuring a profitable and efficient mining operation.

Advanced Technology:

Our gold leaching tanks utilize the latest technology to enhance the leaching process, ensuring that more gold is extracted from your ore. The tanks are designed to provide optimal mixing of the leaching agents, leading to higher recovery rates.

Durable and Robust Design:

Constructed with high-quality materials, our leaching tanks are built to withstand the harsh conditions of mining environments. The robust design ensures a long service life, minimizing downtime and maintenance costs.

Energy Efficiency:

Our tanks are engineered for energy efficiency, reducing the overall power consumption of your leaching process. This not only lowers your operational costs but also minimizes the environmental impact of your mining activities.

Scalable Solutions:

Whether you operate a small-scale mine or a large gold extraction plant, we offer leaching tanks in various sizes and capacities to meet your specific needs. Our scalable solutions ensure that you can find the perfect fit for your operations.

Easy Installation and Maintenance:

Designed for ease of installation and maintenance, our leaching tanks come with detailed instructions and support from our team of experts. This ensures a smooth setup process and minimizes any operational disruptions.

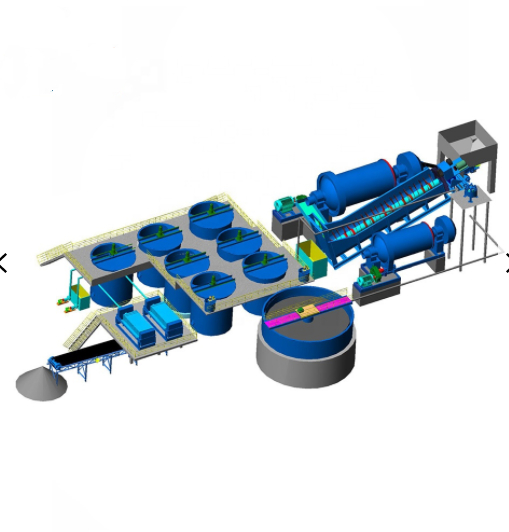

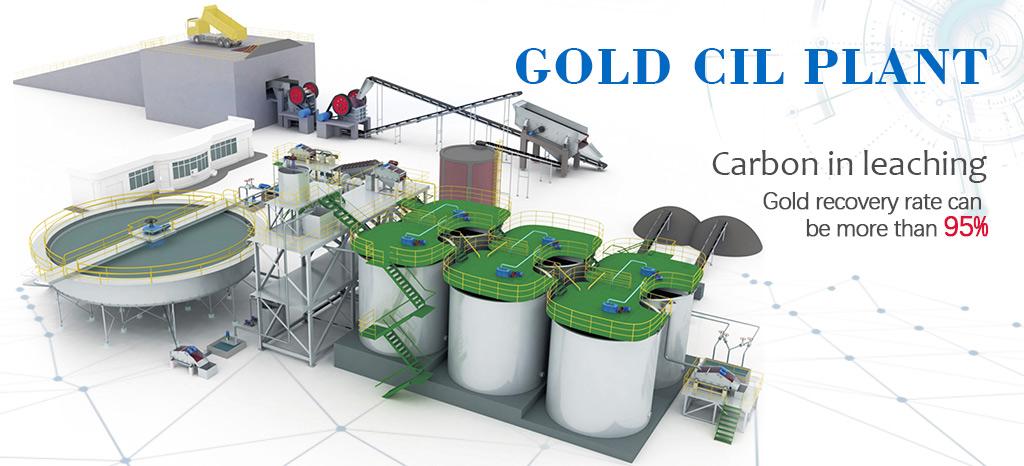

All Slime Cyanidation Carbon-in-leaching Gold Extraction and Smelting Technology (CIL Plant) is a gold-extraction technique in which several major processes are involved. The gold ore is first ground to ore pulp (particles of -200 mesh takes up over 90-95% of the total) which will go through cyanide leaching, and then the soluble gold-bearing minerals in the pulp are directly adsorbed by the activated carbon. Finally, by carbon desorption and electrical winning gold mud is produced. Seven sessions constitute this technique: raw materials preparation, agitation and cyanidation leaching, countercurrent absorption with activated carbon, desorption and electrical winning of gold-bearing carbon, melting and casting following separation and purification of gold mud, reactivation of active carbon and disposal of cyanide-polluted sewage

Frequently Asked Questions (FAQ)

Q: What sizes are available for the Gold Leaching Tanks?

A: We offer a range of sizes to accommodate different mining operations. Please contact us for specific details and recommendations.

Q: How do I install the leaching tank?

A: Our leaching tanks come with detailed installation instructions, and our team is available to provide support throughout the setup process.

Q: What is the expected lifespan of the tank?

A: With proper maintenance, our Gold Leaching Tanks are designed to provide a long service life, ensuring a solid return on your investment.

1.high gold recovery rate

2. adopt a planet-cycloid reducer or flat envelope Reducer drive, high-efficiency to 92%;

3.special structure compared with the same type equipment reducing the motor power, energy-saving rate 27.3%;

4.Little chance of accident happening, high overload capacity;

5. Light weight, low-cost, long service life;

6.low noise;

7.compact structure.

Convenient transportation, crawler walking, no damage to the road, equipped with multi-functional accessories, Drived by oil and electricity.

The whole crushing plant adopts all-wheel drive to realize rotating direction in place, with perfect protection function, especially suitable for narrow and complex site.

The crawler crushing plant could be optional for jaw crusher, impatct crusher, cone crusher, VSI crusher etc.

1)Diameter of impeller is increased, so the peripheral speed of the impeller is increased, agitating ability to pulp and chemical is improved.

2)The impeller is the designed into a pileus type, agitating and cycling ability to pulp and chemicals is improved

3)There equipped with a duck and the impeller is in it. The improvedment of the agitation ability increased the negative pressure caused by slurry movement, which is confined to a limited space by the duct, reinforcing the sucking ability for slurry and chemical and further strengthening the cycling effect of the slurry and chemical

4)The pileus impeller products a downward pressure during running, so that the sucking force is reinforced again, and then the cycling effect of the slurry and chemical is strengthened as well.

5) Beneath the duct, jets are arrrangen, which is also helpful to the cycling. Complete agitation and cycling of the slurry and chemical have the mineral surface to be fully contacted with chemical, being benefit to flotation. Only mineral surface is 100% reagent-contacted, high recovery is guaranteed.

This technology features mature technical skills, high recovery ratio and the final goods are gold bullions.

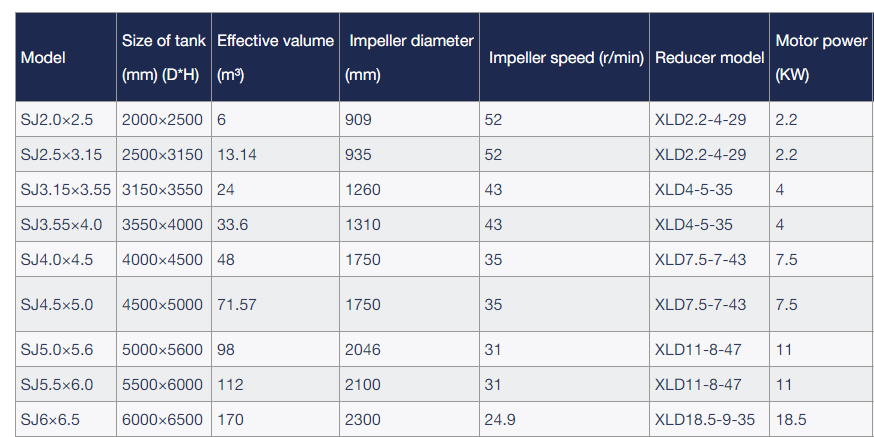

Double-impeller leaching tank is a equipment used for gold cyanidation leaching process and absorption, two transmission ways, one is the planet-cycloid reducer drive; the other is the plane envelope reducer drive.

This equipment working conditions: pulp concentration ≤ 45%, pulp concentration ≤ 1.4 t / m

*The output will vary according to different materials, feed particle size and other factors