Discover Terbaikmachinery's advanced diaphragm filter presses designed for precise filtration in diverse industrial applications. Our membrane filter press technology ensures efficient slurry filtration and solid-liquid separation, enhancing productivity in material processing operations. Trust Terbaikmachinery for expertly crafted filtration solutions that deliver optimal performance and reliability.

Henan Terbaik Machinery Co., Ltd is a leading manufacturer of advanced filtering equipment. Our company is one of the key enterprises specializing in the manufacturing of filter presses. Our product range includes a variety of filtration equipment such as plate and frame filter press, chamber filter press, belt vacuum filter press, membrane filter press, centrifuge, shale shaker, industrial pumps, deep cone thickener, and flotation column. Among these, the diaphragm filter press stands out as an essential piece of equipment for efficient and effective pressurized filtration.

The diaphragm filter press is an intermittent operation pressurized filtration device. It is designed to separate solids from liquids in various industrial processes. The diaphragm filter press operates by using pressure to squeeze the liquid out of the slurry, leaving behind a solid cake. This method ensures maximum filtration efficiency and the production of dry filter cakes.

About Henan Terbaik Machinery Co., Ltd

Henan Terbaik Machinery Co., Ltd is committed to providing high-quality filtering equipment to meet the diverse needs of our clients. With years of experience and expertise, we have established ourselves as a trusted name in the industry. Our focus on innovation, quality, and customer satisfaction ensures that we deliver the best filtration solutions to our clients.

The diaphragm filter press is a versatile and efficient filtration solution widely used in various industries. Here are some key advantages of using a diaphragm filter press:

1. High Filtration Efficiency

The diaphragm filter press is designed to provide excellent filtration efficiency. It ensures maximum separation of solids from liquids, which results in clear filtrate and dry filter cakes. This high level of efficiency makes it suitable for industries where precise filtration is critical.

2. Durability and Reliability

Built with high-quality materials, the diaphragm filter press is known for its durability and long-lasting performance. It is engineered to withstand the rigors of demanding industrial environments, ensuring reliable operation over extended periods.

3. Versatility

The diaphragm filter press is suitable for a wide range of applications across various industries. It is widely used in:

Coal Washing: Essential for removing impurities and water from coal.

Oil Industry: Vital for separating oil from impurities.

Chemicals: Used in chemical manufacturing processes for separating chemical compounds from liquids.

Dyes: Important in dye production for filtering out solids from liquid dyes.

Metallurgy: Crucial in metal processing for separating metal particles from liquids.

Medicine: Used in pharmaceutical production for purifying medicines and medical compounds.

Food Industry: Essential in food processing for separating solids from liquids in products like juices, sauces, and syrups.

Alcohol Production: Used in alcoholic beverage production to filter out solids during fermentation.

Textile and Printing: Important for treating wastewater in textile manufacturing and printing processes.

Pharmaceutical: Used in pharmaceutical production for solid-liquid separation.

Paper Industry: Vital for treating and recycling water used in paper production.

Leather Industry: Used for treating wastewater generated in leather processing.

Urban Sewage Treatment: Essential for treating municipal wastewater to remove solids and purify water.

4. Cost-Effective

The diaphragm filter press helps reduce operational costs by minimizing the need for frequent maintenance. Its ability to produce dry filter cakes makes handling and disposal easier and more cost-effective. This results in significant savings for businesses over time.

5. Environmentally Friendly

The diaphragm filter press contributes to environmental conservation efforts by helping treat industrial wastewater. Its efficient filtration process ensures that harmful solids are separated from liquids, leading to cleaner effluent. This is particularly important for industries looking to minimize their environmental impact and comply with regulatory standards.

The diaphragm filter press is an indispensable piece of equipment for industries requiring efficient and reliable solid-liquid separation. Its high filtration efficiency, durability, versatility, cost-effectiveness, and environmental benefits make it a preferred choice for various applications. Whether it's for coal washing, oil refining, chemical manufacturing, or wastewater treatment, the diaphragm filter press delivers exceptional performance, ensuring optimal results and contributing to sustainable industrial practices

Convenient transportation, crawler walking, no damage to the road, equipped with multi-functional accessories, Drived by oil and electricity.

The whole crushing plant adopts all-wheel drive to realize rotating direction in place, with perfect protection function, especially suitable for narrow and complex site.

The crawler crushing plant could be optional for jaw crusher, impatct crusher, cone crusher, VSI crusher etc.

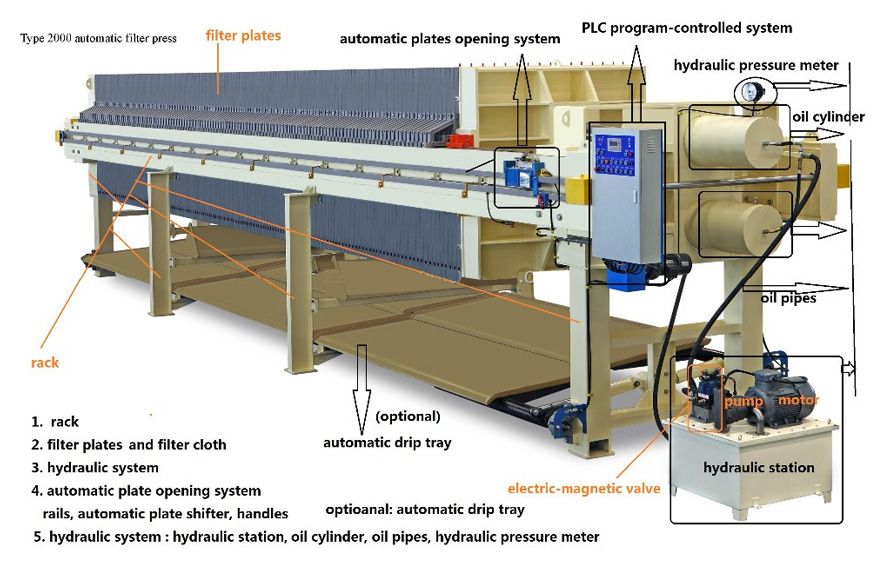

The diaphragm filter press operates through a systematic process of slurry separation, ensuring efficient filtration and dewatering. Here’s a detailed overview of how it works:

1. Preparation and Setup:

All the filter plates are pressed between the movable head plate and the fixed tail plate.

This pressing action creates a series of sealed filtering chambers between adjacent filter plates.

2. Filling the Filter Chambers:

The slurry (a mixture of solids and liquids) is pumped into the filter chambers through the feed pump.

The filter chambers are designed to hold the slurry and facilitate the separation process.

3. Pressure Filtration:

Once the chambers are filled with slurry, the pressure filtration process begins.

The feed pump continues to push the slurry into the chambers, forcing the liquid to pass through the filter cloth.

The solid particles are trapped in the filter chamber by the filter cloth, while the liquid (filtrate) passes through.

4. Filtrate Discharge:

The filtrate is channeled through the filter cloth and exits via the drainage channels on the filter plates.

The filtrate is collected and discharged, completing the liquid separation phase of the process.

5. Dewatering:

The solid particles (now forming a filter cake) are left behind in the filter chamber.

The dewatering process continues until no more filtrate is discharged, indicating that the solids have been sufficiently compacted and dewatered.

6. Completion and Plate Separation:

Once the dewatering process is complete, the feed pump is stopped.

The head plate is moved back to its original position, releasing the pressure on the filter plates.

The filter plates can then be separated, allowing the filter cakes to be removed for further processing or disposal.

The diaphragm filter press operates by creating a series of sealed filtering chambers where slurry is introduced and pressure filtration occurs. Solid particles are retained in the chambers while the filtrate is discharged, resulting in effective separation and dewatering of the slurry. This systematic process ensures high filtration efficiency and reliable operation, making the diaphragm filter press an essential tool in various industrial applications.

*The output will vary according to different materials, feed particle size and other factors