Fluorite ore raw ore is fed into a jaw crusher for coarse comminution by a vibrating feeder, and conveyed by a belt conveyor into a fine crusher (or impact crusher, cone crusher, hammer crusher) for secondary crushing and passing through a vibrating screen. Screening, qualified particle ore through

Fluorite (CaF2) is a mineral used as a source of fluorine in various industries. The beneficiation of fluorite ore can be achieved through gravity separation or flotation, depending on the ore properties. Coarse-grained fluorite is typically sorted using gravity separation, while flotation is used for ore with high mud content, fine particle size, or impurities. Fluorite often coexists with quartz, barite, calcite, and sulfide minerals, necessitating different flotation processes based on ore characteristics.

Gravity Separation Process

Crushing and Screening: The fluorite beneficiation process begins with crushing and screening. Depending on the region and the nature of the fluorite ore, some plants use a three-stage one-closed crushing process, while others use a three-stage open-circuit crushing process. The specific equipment used at this stage includes:

Equipment Stage Equipment Used

Primary Crushing Jaw Crusher

Secondary Crushing Cone Crusher or Impact Crusher

Screening Vibrating Screen

Grinding: Typically, a two-stage grinding process is employed. In cases where fluorite and other minerals coexist as fine particles, the first grinding stage may not fully liberate the fluorite monomers. Coarse grinding of concentrates followed by re-grinding is common for refractory fluorite ore, aiding in better separation during subsequent stages.

Gravity Separation: This method is suitable for high-grade fluorite nuggets and particles (6-20mm). The process is efficient, simple, and convenient, often using diaphragm jigs. These jigs, available as left-handed or right-handed machines, are effective not only for fluorite but also for gold, tin, and tungsten.

Fluorite Flotation Process

Flotation Specificity:

Industrial Requirements: Hydrofluoric acid production requires fluorite with >98% CaF2 and <1% silica. Typically, 5-7 stages of concentration are needed.

Optimal pH: A pulp pH of 8-11 enhances floatability.

Temperature: Increasing the pulp temperature can improve flotation indices.

Application: The flotation process is suitable for fluorite with high silt content, associated impurity minerals, fine disseminated grain size, and complex ore properties.

Process Introduction:

Separation of Fluorite and Sulfide Ore: Use xanthate collectors for sulfide ore, followed by fatty acid collectors for fluorite. Adding a small amount of sulfite inhibitor ensures the quality of the concentrated fluorite.

Separation of Fluorite and Barite: Employ bulk flotation using oleic acid to collect bulk concentrate. Further separation can be achieved through direct or reverse flotation to obtain concentrated fluorite.

Separation of Fluorite and Quartz: Use fatty acid as a collector for fluorite and water glass to restrain quartz. The dosage of water glass must be carefully controlled; too little activates fluorite, while too much restrains it. Sometimes, polyvalent metal ions are added to enhance inhibition, also controlling calcite.

Summary

The processing of fluorite ore involves a combination of gravity separation and flotation, tailored to the specific properties of the ore. Gravity separation is effective for coarse-grained ore, while flotation is necessary for fine-grained, high mud content, and impurity-laden ores. Each method is chosen to optimize the recovery and purity of fluorite, meeting industrial requirements and improving beneficiation efficiency.

Efficient Resource Utilization:

Maximizes the recovery of fluorite from the ore, ensuring minimal loss of valuable material.The fluorite ore beneficiation equipment realizes "more crushing and less grinding", which makes the crushing process save electricity by 60% and greatly reduces the production cost;

Advanced Technology and Equipment:

Utilizes state-of-the-art crushers, ball mills, flotation machines, and classifiers to achieve high efficiency and effectiveness.

Cost Efficiency:

Modern processing techniques and efficient processes lower operational costs, including energy consumption and maintenance expenses.Flotation machine energy-saving up to 60%, flotation agent usage reduced by 20%, recovery rate increased by 1% to 5%;

Environmental Sustainability:

Incorporates waste recycling, water conservation, and pollution control measures to minimize environmental impact.Introduce tailings dry discharge process flow, realize the use of tailings return water circulation, reduce the cost of water use, and reduce the amount of waste water discharge, and reduce the harm to the environment caused by normal mine production.

High-Quality Output:

Produces high-purity fluorite concentrate, meeting industry standards and market demands.

Flexibility:

Capable of processing various ore types and adapting to changes in ore quality, market conditions, and production requirements.

.png)

Convenient transportation, crawler walking, no damage to the road, equipped with multi-functional accessories, Drived by oil and electricity.

The whole crushing plant adopts all-wheel drive to realize rotating direction in place, with perfect protection function, especially suitable for narrow and complex site.

The crawler crushing plant could be optional for jaw crusher, impatct crusher, cone crusher, VSI crusher etc.

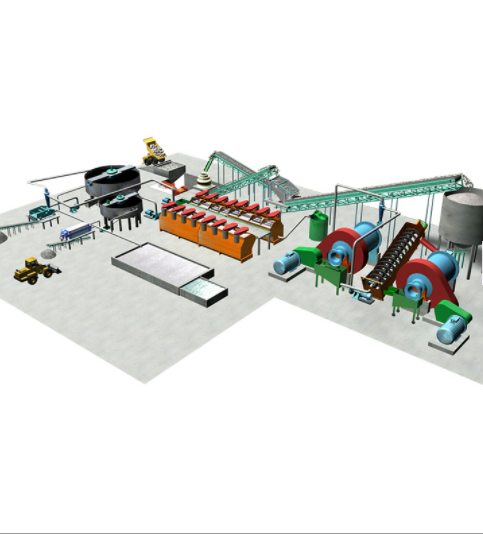

Fluorite ore processing involves several stages to effectively extract and purify the valuable mineral fluorite (CaF₂). The processing line typically includes crushing, grinding, flotation, and other beneficiation methods. Here's a detailed overview of the working principle:

1. Crushing:

Primary Crushing: The fluorite ore is initially fed into a jaw crusher, where large pieces of ore are broken down into smaller, manageable sizes.

Secondary Crushing: The crushed ore is then transferred to cone crushers or impact crushers to reduce the particle size further, preparing it for the grinding stage.

2. Grinding:

Ball Mill: Antimony ore ball mill is based on the characteristics of antimony ore, and improved the design of an efficient and high quality grinding equipment based on the ball mill.

Fluorite Ore Processing plant. The finely crushed ore is then fed into a ball mill, where it is ground into a fine powder. This step is crucial as it liberates the fluorite minerals from the surrounding waste rock.

3. Classification:

Spiral Classifier: Spiral classifier is one of the beneficiation equipments. Spiral classifier is a kind of equipment for mechanical grading by means of the principle that the specific gravity of solid particles is different, and thus the speed of sedimentation in the liquid is different. After grinding, the ore slurry is classified using a spiral classifier to separate fine particles from coarse ones. The fine particles proceed to the flotation process, while the coarse particles may be returned to the ball mill for further grinding.

4. Flotation:

Conditioning: The classified ore slurry is mixed with flotation reagents in conditioning tanks. Common reagents used in fluorite flotation include collectors (like oleic acid), frothers, and modifiers (such as depressants to suppress unwanted minerals).

Flotation Machines: The mixing tank is used for the preparation of flotation agents, pulp storage and the mixing of materials in other industries. The conditioned slurry is then introduced into flotation machines. Air is injected into the slurry, creating bubbles that the fluorite minerals attach to due to their hydrophobic nature.

Froth Formation: Fluorite minerals attach to the air bubbles and rise to the surface, forming a froth layer.

Separation: The froth containing the fluorite is skimmed off, while the remaining waste material (tailings) is left behind.

5. Concentrate Regrinding and Cleaning:

Regrinding: The initial fluorite concentrate obtained from flotation may be reground to further liberate fluorite from impurities.

Cleaning Flotation: The reground concentrate undergoes additional flotation stages to improve purity and grade. This may involve multiple cleaning stages to achieve high-quality fluorite concentrate.

6. Dehydration and Drying:

Dehydration Screens and Centrifugal Dehydrators: The cleaned fluorite concentrate is dehydrated using screens and centrifugal dehydrators to remove excess water.

Dryers: The final concentrate is dried to achieve the desired moisture content, making it suitable for sale or further processing.

7. Tailings Management:

Tailings Disposal: The waste material from the flotation process is managed using tailings ponds or other disposal methods to minimize environmental impact.

.png)

*The output will vary according to different materials, feed particle size and other factors