Terbaikmachinery offers top-of-the-line sand dryers designed for maximum efficiency and performance. Our industrial-grade rotary sand dryers are engineered to deliver precise drying solutions for various applications, including silica sand drying and processing. Trust Terbaikmachinery for expertly crafted drying equipment that ensures optimal moisture removal and enhances productivity in your sand processing operations.

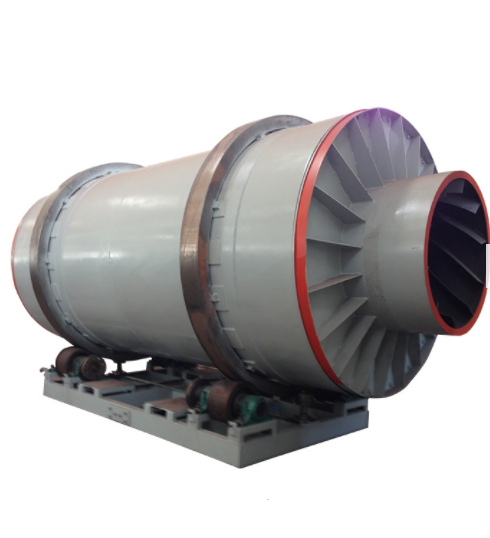

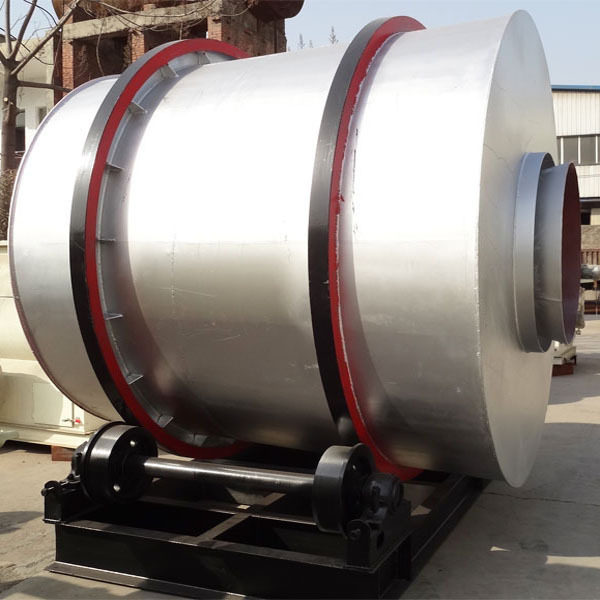

The three-return dryer is a choice equipment for drying non-cohesive materials such as river sand and sand. As long as the materials which can be dispersed naturally after being loosened by hand, they can be dried by a three-return dryer. The main advantage is that the heat preservation effect is better than that of the traditional single drum dryer. The dryer consists of inner drum, middle drum and outer drum to form a self-insulation circulating structure, which has higher working efficiency, more energy-saving and environmental protection.

The three-cylinder dryer is mainly suitable for drying granular materials such as slag, sand, coal, fly ash, iron powder, ore, and quartz sand. It has the following characteristics:

1. The cylinder body is self-protected, and the thermal efficiency can reach 95%. The overall length of the dryer is about 50% less than that of a single cylinder, and the land investment is reduced by about 50%

2. The cylinder is welded with heat-resistant and wear-resistant steel plate, with long service life and convenient maintenance. High thermal efficiency, the temperature of the outer cylinder is below 60℃ (the temperature of the outer single cylinder is as high as 150℃)

3. The temperature of the air outlet is low, and the dust collector has a long service life. It can also be directly connected to the air box pulse bag filter.

4. There is no gear and pinion transmission, but wheel rotation, the whole machine runs horizontally, making the system simple and reasonable.

5. The air heater can be equipped with a boiling furnace or an oil furnace, which can dry materials below 20mm.

6. The final moisture index can be adjusted according to customer requirements.

Convenient transportation, crawler walking, no damage to the road, equipped with multi-functional accessories, Drived by oil and electricity.

The whole crushing plant adopts all-wheel drive to realize rotating direction in place, with perfect protection function, especially suitable for narrow and complex site.

The crawler crushing plant could be optional for jaw crusher, impatct crusher, cone crusher, VSI crusher etc.

1.The material first goes into the inside drum, because there are the spiral shape boards fixed in the drum, when the dryer make rotary working, the spiral shape board will stir the material and make the material do movement.

2.When the material reaches the right side of the drum, it will go into the second drum for further drying.

3.The same working principle, the material then goes into outside drum, during the drying working process, the material will make three times drying, so the material can be dried completely in this process.

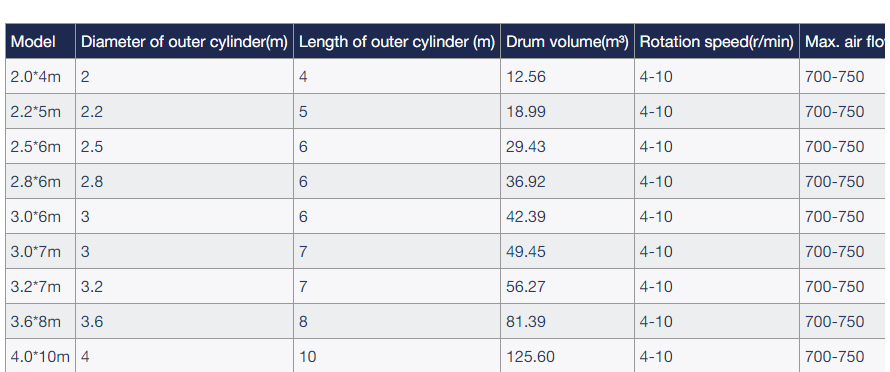

*The output will vary according to different materials, feed particle size and other factors