Explore our comprehensive range of gold ore processing plant solutions at Terbaikmachinery. From efficient gold processing equipment to expertly engineered mineral processing solutions, we provide everything you need to optimize your gold mining operations.

Material Processing

Agglomeration:

Agglomeration Drums: Used in gold heap leaching to enhance the efficiency of the leaching process. Known for reliability and installed in top mines worldwide.

Additional Equipment: Various other agglomeration tools are available to meet specific gold processing needs.

Thermal Processing:

Rotary Dryers and Coolers: Heavy-duty equipment designed for the thermal processing of gold ores.

Bulk Material Handling

Henan Terbaikmachinery provides a range of bulk material handling equipment to facilitate the movement of gold within processing facilities:

Bucket Elevators & Steep Incline Conveyors: For vertical transport of materials.

Troughed Belt Conveyors & Reversing Shuttle Conveyors: For horizontal and versatile material transport.

Additional Features:

Equipment can be outfitted with belt trippers, plows, and belt feeders to enhance system flexibility.

Activated Carbon Regeneration

Rotary Kilns: Used for on-site regeneration/reactivation of activated carbon in the gold cyanidation process.

Process Testing and Design

The Henan Terbaikmachinery Innovation Center offers extensive testing services to ensure process feasibility and optimization:

Feasibility/Proof of Concept: Initial batch testing to explore product creation possibilities.

Proof of Product: Detailed batch testing to determine if a product can meet desired specifications.

Proof of Process: Continuous testing to establish the necessary equipment setup and parameters for consistent production.

Process/Product Optimization: Comprehensive studies to optimize material characteristics and production parameters in an industrial setting.

Parts & Service

Henan Terbaikmachinery offers a broad range of parts and services to maintain equipment performance:

Field Services: On-site support to address equipment needs.

Process and Equipment Audits: Evaluations to ensure optimal operation.

Spare Parts: Availability of essential components for maintenance and repair.

Additional Services: Further support to ensure equipment longevity and efficiency.

For more information on our services and to explore the capabilities of our Innovation Center, visit the Henan Terbaikmachinery website.

Three ways for gold ore processing :

1.Gold cil & cip

2.Gold washing machine & gold Gravity

3.gold flotation.

please see the contents below:

Refractory gold ores, which are not amenable to traditional cyanidation methods, require pre-treatment to expose the gold and improve extraction efficiency. Below are various pre-processing technologies employed to handle such ores.

1.1 Fine Grinding and Screening

The primary goal is to refine ore particles, expose the encapsulated gold, and enhance the efficiency of subsequent processing steps.

Common Equipment:

Ball Mill: Efficient for grinding finer particles.

Autogenous Mill: Uses the ore itself as grinding media.

Rod Mill: Utilizes rods for grinding, suitable for coarse grinding.

Application:

Used to reduce particle size and liberate gold for easier extraction in subsequent processes.

2.1 Chemical Oxidation

This method leverages chemical reactions to oxidize sulfides, making the metal easier to leach.

Common Oxidants:

Oxygen

Hydrogen Peroxide

Application:

Converts sulfides into a more soluble form, facilitating easier leaching and gold recovery.

3.1 Roast Oxidation

Involves heating sulfide ores under high-temperature aerobic conditions to destroy sulfides and release gold.

Process Characteristics:

High-temperature oxidation improves the mineral processing effect.

By-products produced can be recycled.

Fast processing speed and strong adaptability.

Application:

Effective for sulfide-rich ores.

Enhances gold recovery by breaking down sulfide structures.

4.1 Thermal Pressure Oxidation

Uses air or oxygen-rich environments in autoclaves for high-temperature oxidation, breaking down the crystals of sulfide ores and gangue minerals.

Process Characteristics:

Performed in acidic or alkaline media.

Destroys sulfide and gangue mineral structures.

Exposes encapsulated gold, improving cyanide leaching efficiency.

Application:

Suitable for refractory ores with complex sulfide matrices.

Enhances gold extraction by exposing gold particles through oxidation.

Physical Pre-processing: Focuses on grinding and screening to reduce particle size and expose gold.

Chemical Oxidation: Utilizes oxidants to convert sulfides into soluble forms, aiding in gold extraction.

Roast Oxidation: Employs high-temperature aerobic conditions to break down sulfides and release gold.

Thermal Pressure Oxidation: Uses high-temperature, high-pressure oxidation to expose gold, improving leaching efficiency.

Each pre-processing technology is selected based on the specific characteristics of the refractory gold ore to optimize gold recovery and improve overall processing efficiency. Combining these methods with appropriate leaching techniques ensures the best outcomes for challenging ore types.

The above contents detail various methods of gold ore processing, encompassing traditional physical mineral processing, chemical leaching, innovative microbial mineral processing, and pretreatment technologies for difficult gold ores. These methods provide a range of technical options for gold mining. Given the diversity in ore types and properties, it is crucial to tailor the specific ore processing process to the unique characteristics and production requirements of each ore.

Convenient transportation, crawler walking, no damage to the road, equipped with multi-functional accessories, Drived by oil and electricity.

The whole crushing plant adopts all-wheel drive to realize rotating direction in place, with perfect protection function, especially suitable for narrow and complex site.

The crawler crushing plant could be optional for jaw crusher, impatct crusher, cone crusher, VSI crusher etc.

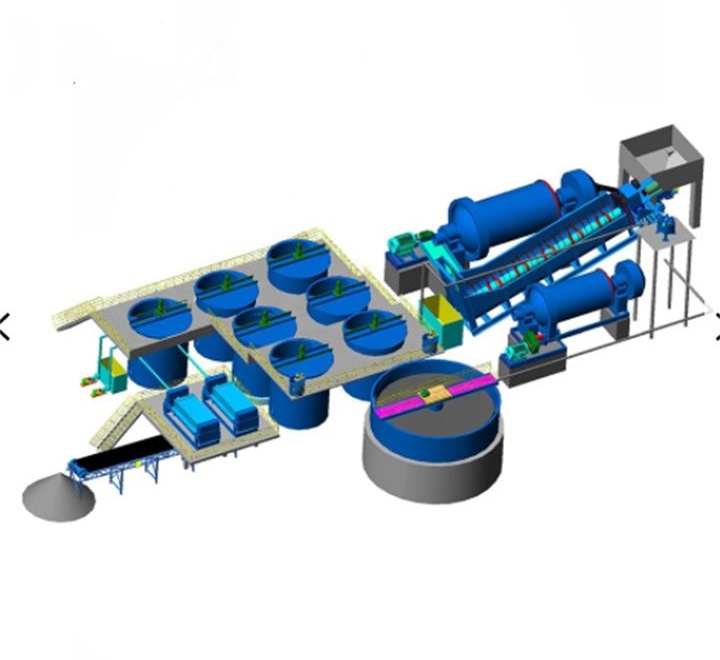

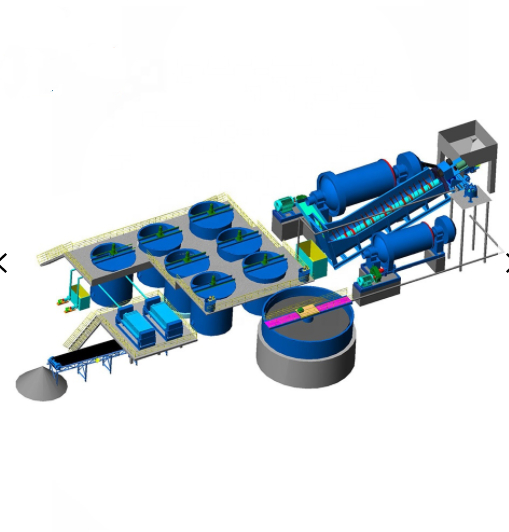

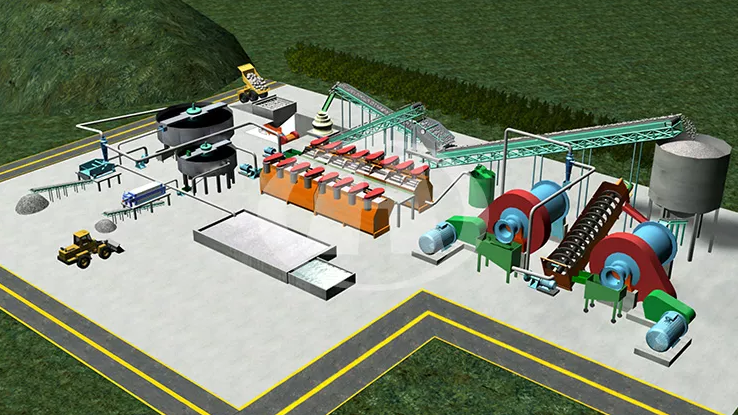

Gold ore processing plants are designed to extract and refine gold from ore using a variety of methods. The processing plant setup is customized based on the specific characteristics of the ore, the production scale, and regulatory requirements. Here, we will outline the general principles and stages of a gold ore processing plant.

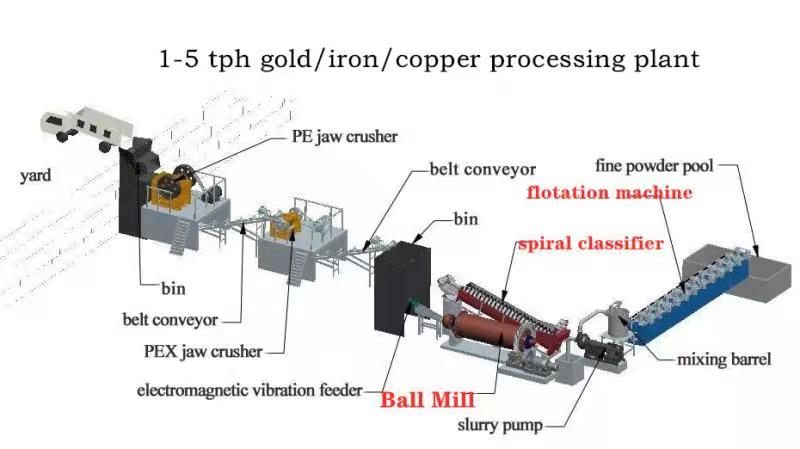

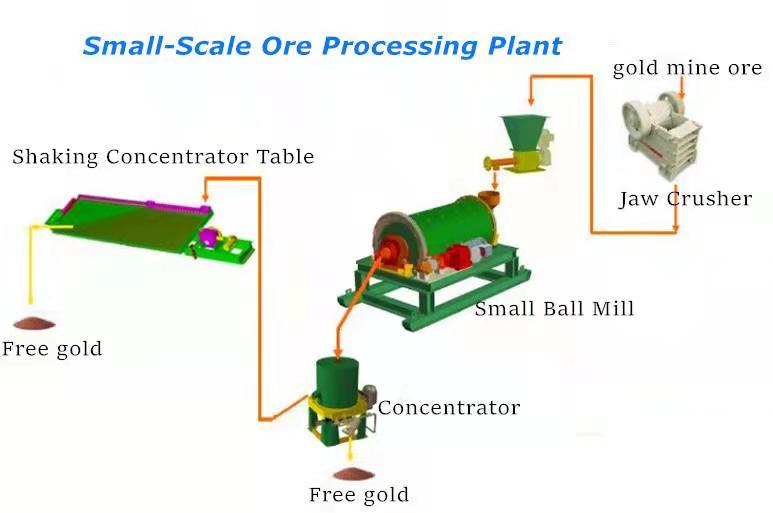

1. Size Reduction

Crushing: Large chunks of gold ore are crushed into smaller pieces using jaw crushers or cone crushers.

Screening: Crushed ore is sorted into different size fractions using industrial screens.

Feeding: Hoppers and feeders transport the crushed ore to the next stage of processing.

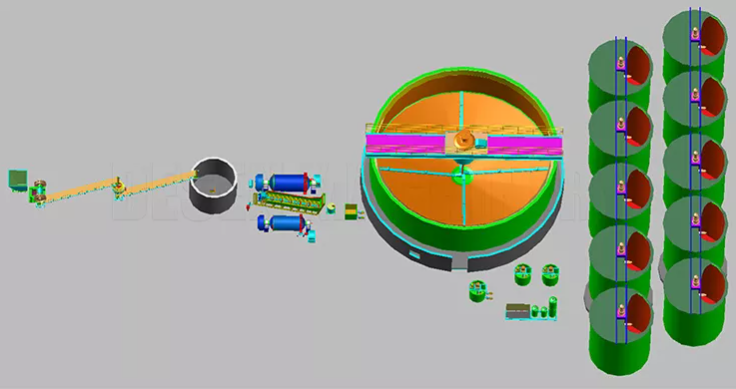

2. Grinding and Classification

Grinding: The crushed ore is further ground using ball mills, rod mills, or autogenous mills to achieve the desired particle size.

Cyclones and Gravity Concentrators: Cyclones are used to classify the ground ore by size, and gravity concentrators (like jigs or shaking tables) are used to separate heavy gold particles from lighter waste materials.

3. Leaching

Agitation Leaching: The ground ore is mixed with a leaching solution (often cyanide) in tanks equipped with agitators to dissolve the gold.

Heap Leaching: For low-grade ores, the ore is stacked in heaps and a leaching solution is sprayed over the heap to dissolve the gold.

4. Gold Recovery

Carbon Adsorption: Gold in the leach solution is adsorbed onto activated carbon.

Electrowinning and Smelting: Gold is recovered from the carbon or leach solution using electrowinning, followed by smelting to produce gold bullion.

Refining: Further purification of gold through refining processes such as the Miller or Wohlwill process.

5. Tailings Treatment

Tailings Management: The leftover materials (tailings) from the processing are treated to remove harmful chemicals and sediments.

Water Reuse: Treated water is often recycled back into the processing plant to minimize water usage and environmental impact.

Crushers: Jaw crushers, cone crushers, impact crushers.

Screens: Vibrating screens, trommels.

Feeders: Vibrating feeders, belt feeders.

Grinding Mills: Ball mills, rod mills, SAG mills.

Gravity Concentrators: Jigs, shaking tables, spiral concentrators.

Leaching Tanks: Agitated tanks, heap leach pads.

Adsorption Systems: Carbon-in-leach (CIL) tanks, carbon-in-pulp (CIP) tanks.

Electrowinning Cells: Used to extract gold from the leach solution.

Smelting Furnaces: Bullion furnaces for melting and refining gold.

Tailings Management Systems: Thickeners, tailings ponds, water treatment systems.

Pumps and Conveyors: Industrial pumps, belt conveyors for material transport.

Electrical Equipment: Generators, control panels for power supply and automation.

Summary

Gold ore processing plants involve multiple stages to extract and purify gold from ore. The process includes size reduction, grinding, leaching, recovery, and tailings treatment. Each plant is customized based on the ore type, production scale, and regulatory requirements. The equipment used in these plants ensures efficient processing and recovery of gold while minimizing environmental impact. Conducting beneficiation tests to determine the ore properties and customizing the process accordingly can significantly improve the economic benefits of gold mining operations.

The gold ore processing plant can be used for gold ore, copper ore, lead ore, zinc ore, fluorite ore, feldspar ore, graphite ore, tungsten ore , chrome ore, iron ore,other metals ore and non-metal ore etc.

We will configure the parameters according to the customer's requirements.

*The output will vary according to different materials, feed particle size and other factors