Explore our comprehensive graphite ore processing line on Terbaik Machinery. Discover industry-leading solutions for graphite beneficiation and processing. Learn about our advanced mineral processing equipment tailored for graphite production. Choose Terbaik Machinery for efficient and reliable graphite ore processing. Contact us for expert assistance and inquiries.

The process flow for lead-zinc ore beneficiation is determined by the type of ore and its specific properties. Different beneficiation methods and equipment are employed accordingly:

Sulfide Ore: Typically treated by flotation.

Oxidized Ore: Treated by flotation, re-election and flotation, or flotation alone. Alternatively, flotation followed by sulfuric acid re-flotation may be used.

Multi-Metal Lead-Zinc Ore: Generally processed using a combination of magnetic-floating, heavy-floating, and heavy-magneto-floating methods.

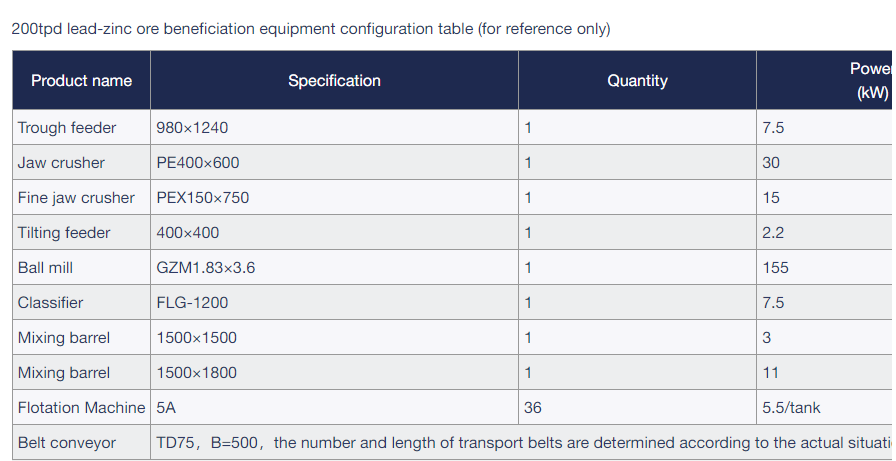

Lead-Zinc Ore Processing Equipment

The lead-zinc ore flotation process often involves several stages, including:

Gravity Beneficiation: This method is usually the initial step, especially for galena (a lead sulfide mineral) which has a coarse embedded particle size. Simple crushing followed by gravity beneficiation using a jigger can yield the desired grade. Advantages include low beneficiation costs, small equipment investment, and effective beneficiation results.

Flotation: After gravity beneficiation, further purification is achieved through flotation to enrich the lead and zinc ores.

Galena Beneficiation

Galena, often associated with zinc ores, has a specific gravity of 7.4-7.6, while the associated vein materials have a specific gravity of less than 3. This significant difference in specific gravity makes galena ideal for gravity separation. The process involves:

Crushing: Simple crushing to separate lead minerals from the veins.

Jigging: Using a jig machine, galena is sorted based on the specific gravity difference. This method yields excellent beneficiation results with satisfactory beneficiation indexes.

Gravity Concentration Using Jigger

The jigger is a common gravity concentrator used to sort galena. It exploits the specific gravity difference between galena and its associated vein materials, achieving effective separation and producing a high-grade concentrate. In practice, gravity beneficiation of galena is straightforward, efficient, and yields impressive beneficiation outcomes.

In summary, the lead-zinc ore beneficiation process varies according to ore type and specific characteristics. Techniques like flotation, gravity beneficiation, and combined methods are tailored to optimize the recovery and enrichment of lead and zinc minerals.

1. Novel Beneficiation Process with Lower Operating Costs:

Innovative Regrinding Process: The lead-zinc copper mixed concentrate regrinding process eliminates the necessity of grinding all the raw ores, significantly saving grinding costs.

Enhanced Dissociation: This process allows the concentrate to be reground to further dissociate lead and zinc concentrates, offering a good dedoping effect. This creates favorable conditions for the separation of lead and zinc from difficult substances.

2. Strengthened Flotation Process to Improve Concentrate Grade:

Strict Pharmacy System Implementation: In the rough election segment, strict control of the amount of pharmaceuticals ensures that "early income can be received early," reducing multiple cycles and inaction losses.

Secondary Foam Enrichment: The flotation process makes full use of the secondary enrichment of the foam. By appropriately rinsing the concentrate foam without water, impurities in the foam are reduced, enhancing flotation and improving the concentrate grade.

3. Efficient Resource Utilization:

Optimized Recovery Rates: Designed to maximize the recovery of lead, zinc, and copper from the ore, ensuring minimal loss of valuable material.

Comprehensive Processing: Adapts to various ore types and grades, optimizing the use of available resources.

4. Advanced Technology and Equipment:

State-of-the-Art Machinery: Utilizes advanced crushers, ball mills, flotation machines, and other specialized equipment to achieve high efficiency and effectiveness.

Automation and Control: Incorporates modern control systems and automation, reducing human error, increasing precision, and enhancing productivity.

5. High-Quality Products:

Purity and Consistency: Advanced processing techniques ensure the production of high-purity lead, zinc, and copper, meeting industry standards and market demands.

Customizable Output: Plants can produce different grades and specifications of metals, catering to various industrial applications and customer requirements.

6. Increased Operational Efficiency:

Streamlined Processes: Integrated processing lines ensure smooth transitions between crushing, grinding, flotation, and other stages, reducing downtime and improving throughput.

Flexibility: Modern plants can quickly adapt to changes in ore quality, market conditions, and production requirements, maintaining high efficiency and productivity.

Overall, lead & zinc, copper ore processing plants are crucial for efficient resource utilization, cost-effective operations, environmental sustainability, high-quality product output, and economic development, making them indispensable in the mining and metals industry.

Convenient transportation, crawler walking, no damage to the road, equipped with multi-functional accessories, Drived by oil and electricity.

The whole crushing plant adopts all-wheel drive to realize rotating direction in place, with perfect protection function, especially suitable for narrow and complex site.

The crawler crushing plant could be optional for jaw crusher, impatct crusher, cone crusher, VSI crusher etc.

The processing of lead, zinc, and copper ores involves several stages to extract the valuable metals. Here’s a detailed overview of the working principle:

1. Crushing:

Primary Crushing: The ore is initially crushed by jaw crushers, which break the large rocks into smaller pieces suitable for further processing.

Secondary and Tertiary Crushing: The crushed ore is further reduced in size using hydraulic cone crushers and hammer crushers to achieve the desired particle size.

2. Grinding:

Ball Mill: The crushed ore is then ground in ball mills, which are key equipment for further reducing the ore size. The ball mills grind the ore to a fine powder, enabling the liberation of the valuable minerals from the waste rock.

3. Classification:

Spiral Classifiers: The ground ore is classified using spiral classifiers to separate fine particles from coarse ones. This ensures that only appropriately sized particles proceed to the next stage.

4. Flotation:

Flotation Machines: The classified ore is then subjected to flotation in SF-type and XJK-type flotation machines. The flotation process involves adding reagents such as kerosene, No. 2 oil, water glass, and lime to the slurry to enhance the hydrophobic properties of the valuable minerals.

Mixing and Conditioning: The ore slurry is mixed and conditioned in flotation cells to ensure proper reagent interaction with the minerals.

Froth Formation: Air is introduced into the flotation cells, creating bubbles that attach to the hydrophobic minerals, forming a froth layer.

Separation: The froth, containing the valuable minerals, is skimmed off the surface, while the remaining waste material (tailings) is discarded.

5. Regrinding and Cleaning:

Concentrate Regrinding: The initial concentrate obtained from the flotation process is reground to further liberate the lead and zinc minerals. This regrinding process may be repeated multiple times (3-7 times, typically 3-4 times) to enhance the purity and grade of the concentrate.

Cleaning Flotation: The reground concentrate undergoes additional flotation stages to improve the separation of lead and zinc. This involves the use of secondary foam enrichment and rinsing techniques to reduce impurities and enhance flotation performance.

6. Dehydration and Drying:

Dehydration Screens and Centrifugal Dehydrators: The cleaned concentrate is subjected to dehydration using screens and centrifugal dehydrators to remove excess water.

Dryers: The final concentrate is dried to achieve the desired moisture content, making it suitable for further processing or sale.

7. Tailings Management:

Tailings Disposal: The waste material from the flotation process (tailings) is managed using tailings ponds or other disposal methods to minimize environmental impact.

8. Additional Processing for Specific Metals:

Lead and Zinc: Lead and zinc concentrates may undergo further processing to separate the two metals. This involves additional regrinding and flotation steps to achieve high-purity lead and zinc concentrates.

Copper: Copper concentrates may be processed through smelting and refining to produce high-purity copper metal.

Novel Beneficiation Process: The regrinding process for mixed concentrates reduces the need for grinding all raw ores, lowering operating costs.

Enhanced Flotation: Strengthened flotation techniques, including strict control of reagent amounts and secondary foam enrichment, improve the concentrate grade and overall recovery rates.

Advanced Equipment: Utilizes state-of-the-art machinery, such as jaw crushers, ball mills, flotation machines, and spiral classifiers, to ensure efficient and effective ore processing.

Environmental Sustainability: Incorporates waste recycling, water conservation, and pollution control measures to minimize environmental impact.

High-Quality Output: Produces high-purity lead, zinc, and copper concentrates, meeting industry standards and market demands.

By following these principles, the lead & zinc, copper ore processing plant efficiently extracts valuable metals from the ore, ensuring high recovery rates, cost-effective operations, and sustainable environmental practices.

*The output will vary according to different materials, feed particle size and other factors