Terbaikmachinery offers high-efficiency hydro cyclones designed for superior particle separation in mineral processing operations. Our hydrocyclone separators utilize centrifugal force to efficiently separate solids from liquids, enhancing solid-liquid separation and ore beneficiation processes. Trust Terbaikmachinery for expertly crafted separation solutions that ensure optimal performance and maximize mineral recovery.

A hydrocyclone, also known as a cyclone, is a classifying device that utilizes centrifugal force to accelerate the settling rate of slurry particles and separate particles based on size, shape, and specific gravity.

A hydrocyclone is a simple, cone-shaped cylindrical container with no moving parts. It is used to separate or “cut” solid particles in a liquid stream by size and density.

A hydrocyclone consists of:

A cylindrical top with an offset feed inlet pipe

An overflow outlet on top

Tapered cone(s) leading down to a small outlet at the bottom

Other parts include:

External casings that contain the internal pressure and are clamped or bolted together

Internal replaceable liners for wear resistance

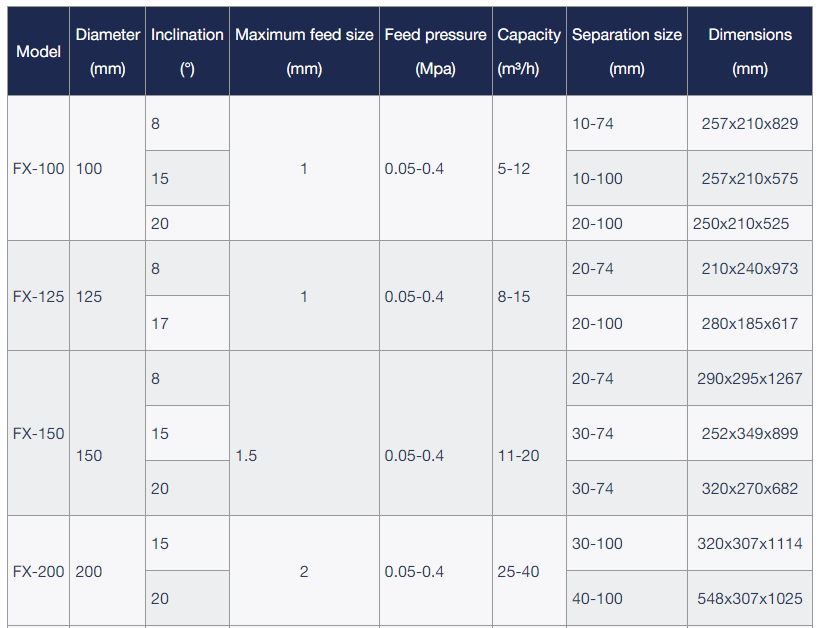

Typical cyclone diameters range from 10mm for very fine cuts to 1,000mm or more for larger cuts.

Hydrocyclones are mainly applied to processes such as second paragraph grinding, coarse or concentrate re-grinding, and closed-circuit operations with mechanical grading machines. These devices operate by grading particles according to their size and have features like:

Simple structure

Long service life

Large disposal capability

Small land footprint

No driving power consumption

They are highly efficient for grading and de-sliming fine-particle materials and are widely used in concentrators of nonferrous and ferrous metals, chemical, pharmaceutical, ceramics, and other industries.

Hydrocyclones are widely used in both black and non-ferrous metal mines for:

Grinding

Grading

Concentration

Dewatering

Desliming

Ultra-fine grading

Tailings filling

Damming

Recycling processes

Efficiency: High efficiency in particle separation due to centrifugal force.

Durability: Long-lasting with replaceable liners for wear resistance.

Capacity: Capable of handling large volumes with minimal land use.

Cost-Effectiveness: Low price compared to other separation methods.

Space-Saving: Small area required for installation.

Power Consumption: Despite requiring pressure for feeding, it offers high classification efficiency and very fine overflow.

Factors Affecting Efficiency and Wear

Several factors influence the efficiency and wear of hydrocyclones:

Particle Size: Uniform particle size improves separation efficiency.

Slurry Density: The density of the slurry affects the centrifugal force and separation rate.

Flow Rate: Consistent flow rate ensures optimal performance.

Material Abrasiveness: High abrasiveness increases wear on internal liners.

Selection:

Determine the required cut size based on your application.

Choose the appropriate cyclone diameter.

Consider the material of construction for durability and wear resistance.

Installation:

Ensure proper alignment of the feed inlet, overflow, and underflow outlets.

Secure the hydrocyclone to handle the internal pressure.

Install replaceable liners for easy maintenance.

Adjusting Hydrocyclone Performance

To achieve optimal performance, you may need to adjust:

Feed Pressure: Higher pressures increase separation efficiency but can cause more wear.

Vortex Finder Diameter: Smaller diameters improve fine particle separation.

Underflow Orifice Size: Adjusting the size can help control the underflow discharge rate.

By understanding these fundamentals and tips shared by Chris Lowe, you can optimize the use of Terbaik® hydrocyclones in your operations, ensuring high efficiency and longevity of your equipment. For more detailed parameters or specific inquiries, feel free to contact us directly.

Long Service Life: The use of high-performance polyurethane material extends the lifespan of hydrocyclones.

Low Capital Cost: Hydrocyclones are cost-effective in terms of initial investment.

High Efficiency: Effective in separating particles ranging from 5 to 200 microns.

Reduced Wear: The absence of moving parts minimizes wear and tear.

Minimal Downtime: Continuous or batch removal of underflow requires little to no maintenance downtime.

Compact Size: Hydrocyclones are smaller compared to other separation equipment.

Versatile Operation: Can function across a wide range of temperatures and pressures.

Advantages of High-Fineness Particle Classifiers

Adjustable Fineness: Achieves product fineness up to D97: 3 microns, with adjustable particle sizes.

High Output: Delivers high fineness with a large output.

Effective Sealing: Small gaps and gas seals prevent large particles from entering.

Design Variability: Available in horizontal single rotor and horizontal multiple rotor configurations, allowing user customization.

High Performance: Multi-rotor classifiers ensure high output and maintain accuracy at the cutting point.

Material Flexibility: Grade wheels can be made from carbon steel, stainless steel, ceramics, polyurethane, and other materials based on customer needs.

Environmental Compliance: Operates under negative pressure, meeting national environmental protection standards for dust emission.

Convenient transportation, crawler walking, no damage to the road, equipped with multi-functional accessories, Drived by oil and electricity.

The whole crushing plant adopts all-wheel drive to realize rotating direction in place, with perfect protection function, especially suitable for narrow and complex site.

The crawler crushing plant could be optional for jaw crusher, impatct crusher, cone crusher, VSI crusher etc.

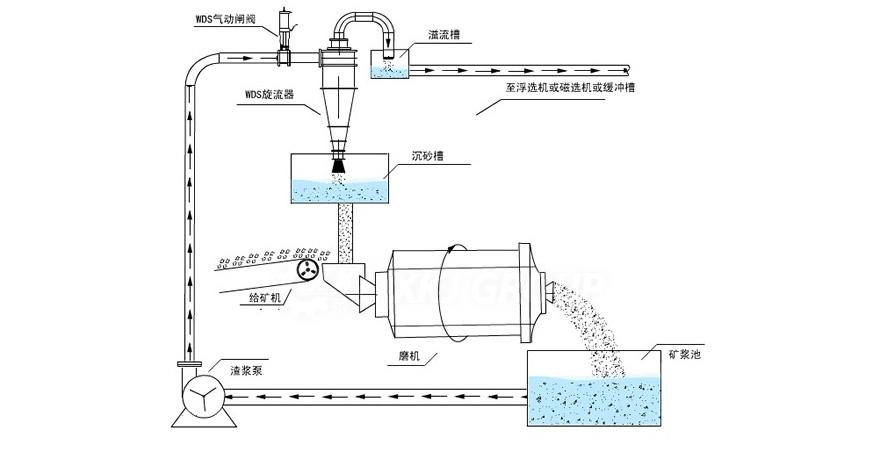

A hydrocyclone operates by utilizing the principles of centrifugal force and fluid dynamics to separate particles from a liquid. When a mixture of solids and water is pumped into the hydrocyclone under high pressure, it creates a swirling motion within the cylindrical body of the cyclone. This rotational movement causes the heavier solid particles to be flung outward to the wall of the cylinder due to centrifugal force. These larger particles then move downward due to gravity and exit through the bottom outlet, carrying with them a small amount of water. Meanwhile, the finer particles and most of the water remain closer to the center of the cyclone, forming a spiral that moves upwards around an air core. This mixture is then expelled through a central pipe, known as the vortex finder, and exits at the top overflow.

Hydrocyclone Structure

A hydrocyclone is typically constructed with a cylindrical section that transitions into a conical section. The feed, containing a suspension of particles, is injected tangentially at high speed into the upper cylindrical section. This creates a strong swirling fluid motion. As the fluid spirals downward, the coarser particles are separated and discharged through the underflow orifice at the cone tip, while the finer particles and most of the liquid exit through the overflow pipe at the top.

Working Principle of a Hydrocyclone

The design of a hydrocyclone consists of a conically shaped vessel that is open at its apex, also known as the underflow, and connected to a cylindrical section with a tangential feed inlet. The top of the cylindrical section is sealed with a plate, through which an axially mounted overflow pipe passes. The feed enters the hydrocyclone under pressure through the tangential inlet, imparting a swirling motion to the slurry inside. This motion generates a vortex within the cyclone. The lighter particles are carried upwards and out through the overflow pipe by the vortex, while the heavier particles are directed downwards and discharged with the slurry through the underflow outlet.

Particle Classification Process

As the material enters the classifier's lower entrance, it is propelled into the classification area by the upward airflow generated by the fan's suction force. The high-speed rotation of the classification turbine creates a strong centrifugal force, which separates the coarse and fine particles. Fine particles that meet the required size criteria are carried through the blade gap into a cyclone separator or dust collection device. Coarse particles, which may still contain some fine particles, lose their speed and, along with the fine particles, descend along the cylinder wall to the secondary air outlet. Here, they are subjected to the strong translational action of the secondary air, further separating the particles. The finer particles rise to a second level for additional classification, while the coarser particles fall to the discharge port for removal.

In summary, the hydrocyclone’s efficiency in separating particles relies on the intricate interplay of centrifugal force, fluid dynamics, and precise design. Its structure and operational principles make it a vital component in various industries for particle classification and separation.

*The output will vary according to different materials, feed particle size and other factors