Terbaikmachinery offers high-quality ceramic filters designed for superior filtration performance in various industries. Our industrial-grade ceramic filtration equipment is engineered to effectively separate solids from liquids, providing efficient slurry filtration and solid-liquid separation. Trust Terbaikmachinery for expertly crafted filtration solutions that ensure optimal performance and enhance productivity in your material processing operations.

The ceramic filter is a high-efficiency filtration equipment designed to meet the demanding needs of the mining industry. It features a robust construction and advanced filtration technology, ensuring reliable performance and energy savings in various applications.

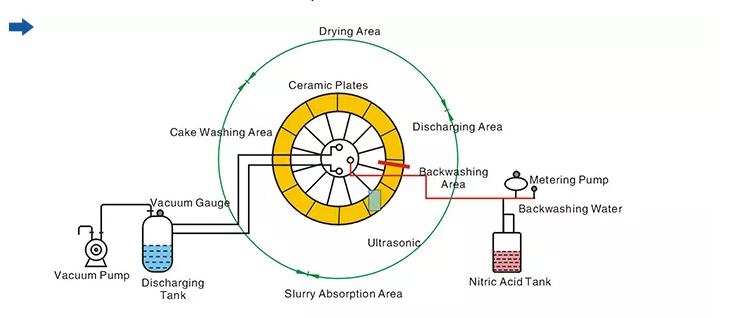

Components of the Ceramic Filter

The ceramic filter is mainly composed of the following systems and components:

Roller System: Facilitates the rotation and movement of the filter plates.

Mixing Discharge System: Ensures uniform distribution of slurry and efficient discharge of filtered materials.

Vacuum System: Creates the necessary vacuum pressure for filtration.

Liquid Discharge System: Manages the removal of filtrate from the system.

Scraper System: Removes the filter cake from the surface of the plates.

Anti-Flushing System: Prevents clogging and maintains the efficiency of the filter.

Combined Cleaning System: Incorporates automatic ultrasonic cleaning and acid cleaning for thorough maintenance.

Automatic Control System: Provides precise control and automation of the filtration process.

Tank and Frame: Supports the entire filtration setup and ensures stability.

Applications in the Mining Industry

The ceramic filter is widely used in various mining applications, including:

Non-Ferrous Metals: Efficiently processes ores and concentrates of metals like copper, zinc, and aluminum.

Rare Metals: Suitable for the filtration of rare metal concentrates.

Ferrous Metals: Used in iron ore and steel production processes.

Non-Metals: Effective in the filtration of non-metallic minerals.

Concentrate and Tailing Dehydration: Ensures efficient dehydration of mining concentrates and tailings.

Chemical Industry: Applicable in the filtration of chemical solutions and slurries.

Electrolytic Oxide Slag: Filters slag generated from electrolytic processes.

Leaching Slag: Used in the separation of leaching residues.

Slag Dewatering and Waste Acid Treatment: Facilitates the dewatering of slag and treatment of acidic wastewater.

Sewage Sludge Treatment: Provides effective filtration of sewage sludge.

Material Fineness and Filtration Efficiency

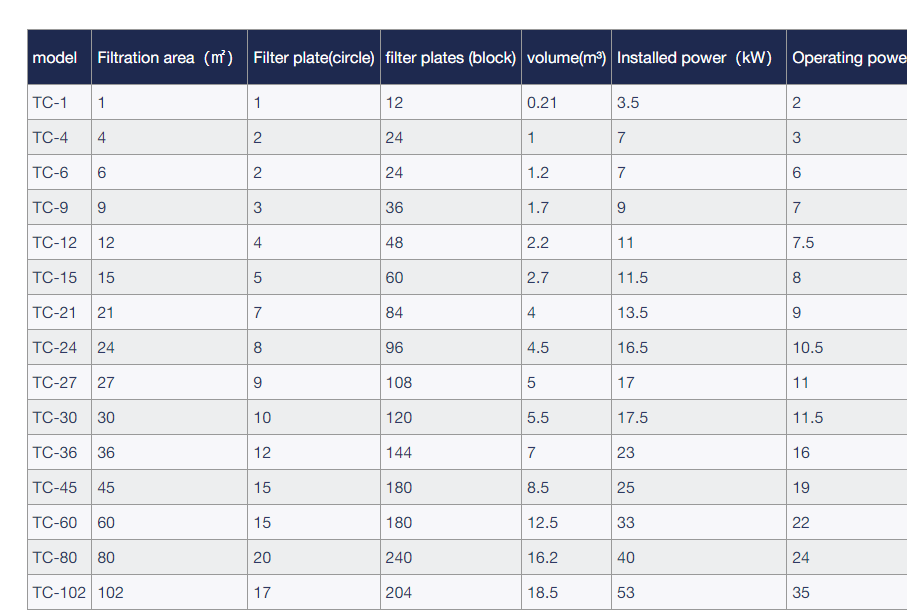

The ceramic filter is designed to handle material fineness ranging from -200 to -450 mesh and other various superfine materials. This makes it highly versatile and suitable for a wide range of filtration needs in the mining industry.

1. vacuum degree( 0.09-0.098MPa), low moisture of filter cake;

2. The add solid content is less than 50ppm. Can be used repeatedly, reducing emissions;

3. The increase compared with traditional ceramic filter cake washing, apply to washing materials;

4. PLC, microcomputer combined with automatic valve control, high degree of automation, reduce labor intensity

5. The compact, small footprint, easy installation and maintenance;

6. The drainage system is advanced, suitable for use in any operating conditions.

Convenient transportation, crawler walking, no damage to the road, equipped with multi-functional accessories, Drived by oil and electricity.

The whole crushing plant adopts all-wheel drive to realize rotating direction in place, with perfect protection function, especially suitable for narrow and complex site.

The crawler crushing plant could be optional for jaw crusher, impatct crusher, cone crusher, VSI crusher etc.

Filter disc moves slowly in the pulp tank, with the formation of vacuum pump pressure difference, made the solid particles adsorbed on the disc filter cloth, and form the filter cake with a certain thickness.

The filtrate through filter cake and filter cloth discharge from the central axis of the filter cake with the pressure of air blower blade, the filter cake fell into the discharge cake tank.

Operational Zones

Slime Absorbing Zone: The filter plate is immersed in the slime, initiating the surface adsorption of the filter cake.Capillary action, combined with vacuum pressure, draws the filtrate into the distributing valve and drainage tank through the filter plate.In this zone, the filter plate immerses in the pulp tank where slurry (slime) surrounds it. The vacuum pressure and capillary action ensure the initial adsorption of solid particles onto the filter cloth.The vacuum pressure creates a difference that draws the filtrate through the filter cloth while solid particles are left behind, forming a filter cake on the cloth surface.

Leaching Zone: The filter cake exits the slime hopper and undergoes spray washing to remove any residual slime or contaminants.The filter cake, once formed, moves out of the pulp tank and enters the leaching zone where it is sprayed with water or another washing solution to remove impurities.The spray washing helps to remove any trapped residuals within the filter cake, enhancing the purity of the solid output.

Drying Zone: The filter cake undergoes continuous dehydration under high vacuum force, ensuring maximum removal of moisture.After leaching, the filter cake passes through the drying zone where additional moisture is removed.A high vacuum force continues to extract moisture from the filter cake, ensuring it is as dry as possible before discharge.

Discharging Zone: As the filter cake enters a vacuum-free condition, a scraper automatically discharges the materials from the filter plate. In this zone, the now-dried filter cake is removed from the filter plate.The scraper mechanism automatically discharges the filter cake from the filter plate as it exits the vacuum condition, depositing it into the discharge cake tank.

Back Flushing: Service water or filtrate is directed through the ceramic plate via the distributing valve, cleaning any blocked mini-holes.

Periodic cleaning with ultrasonic waves and low-density acid helps maintain the ceramic plate’s efficiency and extends its service life.This step ensures the maintenance of the filter’s efficiency by cleaning the ceramic plates.Service water or filtrate is flushed through the ceramic plates to clear any blockages in the mini-holes. Additionally, ultrasonic cleaning and low-density acid treatment are periodically used to ensure the ceramic plates remain clean and functional over long-term use.

The ceramic filter’s methodical operation, featuring distinct zones for slime absorption, leaching, drying, discharging, and back flushing, ensures high-efficiency solid-liquid separation. Its design and process not only optimize filtration performance but also extend the operational life of the ceramic plates, making it a valuable asset in various industrial applications, especially within the mining industry.

*The output will vary according to different materials, feed particle size and other factors