Terbaikmachinery offers Jaw Crushers for reliable crushing solutions in various industries. Jaw Crushers ensure efficient material crushing, enhancing productivity and product quality. Trust Terbaikmachinery for expertly crafted crushing solutions.

China Hot sale PE Series 250 400 600 900 Jaw crusher

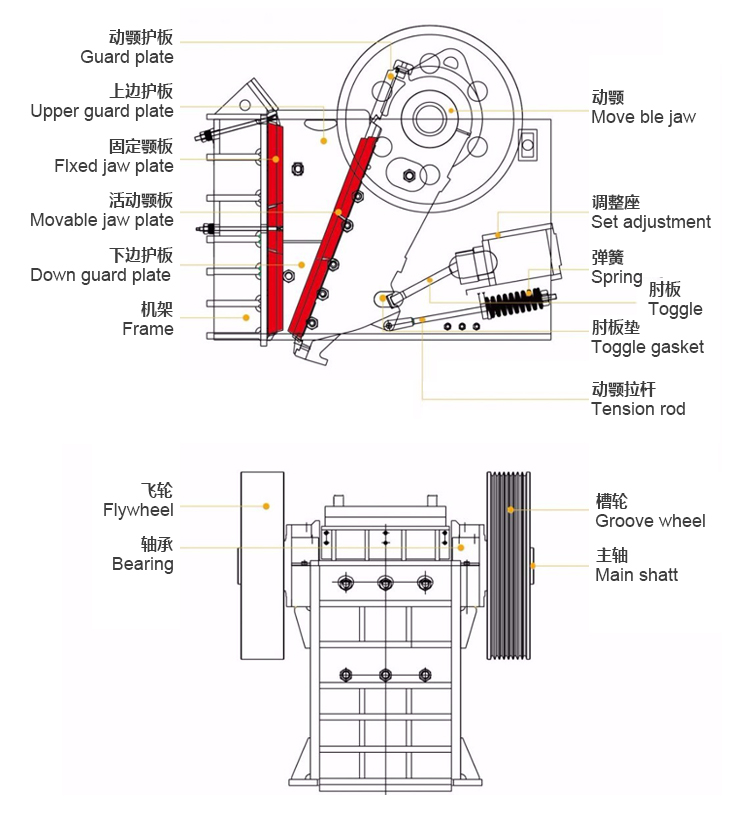

Jaw crusher commonly known as jaw crusher, also known as tiger jaw. The crushing chamber is composed of two jaw plates, the moving jaw and the static jaw, which simulate the movement of the two jaws of animals to complete the material crushing operation. It is widely used in the crushing of various ores and large materials in the mining and smelting, building materials, highways, railways, water conservancy and chemical industries. The maximum compressive strength of the crushed material is 320Mpa.

What are the best-selling models of jaw crushers?

Unique Flywheel Design: Reduce vibration effectively, Machine work is stable

Large Crushing Ratio: low suspension motion mechanism leads to greater crushing ratio.

Easy To Maintain: Application of high wear-resisting toothed plate, long maintenance period, and cost-saving.

Low Failure Rate: Reliable performance, optimized design, the low failure rate.

Exploring the versatility and Benefits of PE Jaw Crushers

Convenient transportation, crawler walking, no damage to the road, equipped with multi-functional accessories, Drived by oil and electricity.

The whole crushing plant adopts all-wheel drive to realize rotating direction in place, with perfect protection function, especially suitable for narrow and complex site.

The crawler crushing plant could be optional for jaw crusher, impatct crusher, cone crusher, VSI crusher etc.

The movable jaw is hung on the mandrel and can swing left and right. When the eccentric shaft rotates, the connecting rod reciprocates up and down, which drives the two thrust plates to also reciprocate, thereby pushing the movable jaw to reciprocate left and right to realize crushing and unloading. This type of crusher adopts a crank double-link mechanism. Although the movable jaw is subjected to a great crushing reaction force, its eccentric shaft and connecting rod are not subjected to much force. Therefore, large-scale and medium-sized machines are often used in the industry. Come to crush hard materials. In addition, when this type of crusher works, the motion trajectory of each point on the movable jaw is an arc centered on the mandrel, the arc radius is equal to the distance from the point to the axis, the upper arc is small, and the lower arc is large. The crushing efficiency is low, and the crushing ratio is generally 3-6. Because of its simple movement trajectory, it is called simple swing jaw crusher.

How to extend the service life of jaw crusher ?

| Model | Feed (mm) | Max. (mm) | Adjusting (mm) | Processing capacity (m/h) | Motor power (Kw) | Total weight (t) |

| PE-250×400 | 250×400 | 210 | 20-60 | 3-13 | 15 | 2.8 |

| PE-400×600 | 400×600 | 340 | 40-90 | 10-35 | 30 | 7 |

| PE-500×750 | 500×750 | 425 | 50-100 | 25-60 | 55 | 10.6 |

| PE-600×900 | 600×900 | 500 | 65-180 | 30-85 | 55-75 | 15.5 |

| PE-750×1060 | 750×1060 | 630 | 80-180 | 72-150 | 90-110 | 28 |

| PE-800×1060 | 800×1060 | 680 | 100-200 | 85-143 | 90-110 | 30 |

| PE-870×1060 | 870×1060 | 750 | 170-270 | 145-235 | 90-110 | 30.5 |

| PE-900×1060 | 900×1060 | 780 | 200-290 | 170-250 | 90-110 | 31 |

| PE-900×1200 | 900×1200 | 780 | 95-255 | 100-240 | 110-132 | 49 |

| PE-1000×1200 | 1000×1200 | 850 | 195-280 | 190-275 | 110-132 | 51 |

| PE-1200×1500 | 1200×1500 | 1020 | 150-300 | 250-500 | 160 | 100.9 |

| PEX-150×750 | 150×750 | 120 | 18-48 | 5-16 | 15 | 3.5 |

| PEX-250×750 | 250×750 | 210 | 25-60 | 8-22 | 22 | 4.9 |

| PEX-250×1000 | 250×1000 | 210 | 25-60 | 10-32 | 30-37 | 6.5 |

| PEX-250×1200 | 250×1200 | 210 | 25-60 | 13-38 | 37 | 7.7 |

| PEX-300×1300 | 300×1300 | 250 | 20-90 | 10-65 | 75 | 11 |

Exploring the Versatility and Benefits of PE Jaw Crushers

If you needs others stone crusher , it is also avaiable

*The output will vary according to different materials, feed particle size and other factors