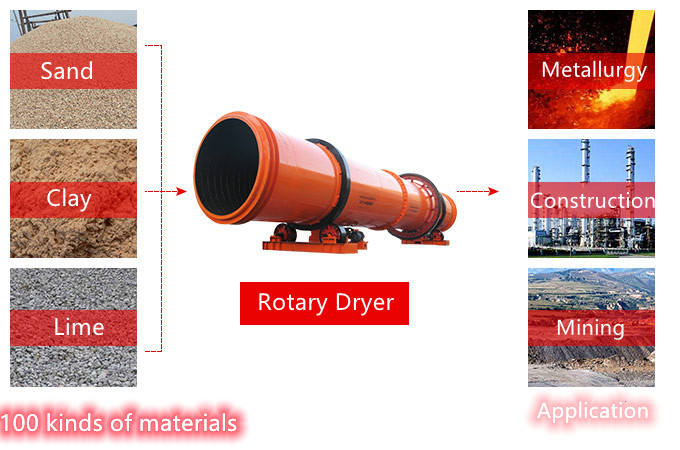

Terbaikmachinery offers high-quality rotary dryers designed for efficient drying solutions. Our industrial-grade dryers utilize advanced technology to ensure thorough and uniform drying of bulk materials, enhancing productivity and product quality. Trust Terbaikmachinery for expertly crafted drying solutions.

Henan Terbaik Machinery is renowned for being the top rotary dryer manufacturer in the industry. We custom design each dryer to meet the specific processing needs of your material. Whether you need low or high inlet temperatures, short or long residence times, counter-current, or co-current flow, our design team can create the ideal rotary drum dryer for your application.

Highly Efficient: Suitable for bulk solids with robust processing capabilities.

Custom Designed: Tailored to the unique needs of your material.

Uniform Results: Consistent performance despite variations in feedstock.

Rotary dryers operate by tumbling material in a rotating drum with drying air. The drum is slightly inclined horizontally, enabling gravity to help move the material through the drum. As the drum rotates, lifting flights pick up the material and drop it through the air stream to maximize heat transfer efficiency. Indirect heating can be used to prevent direct contact between the material and the processing medium.

Enhanced Heat Transfer: Lifting flights and tumbling action ensure efficient drying.

Additional Processing: Tumbling can further round and polish granules when working with agglomerates.

The sludge dryer is specifically designed for drying sludge with high moisture, viscosity, water holding capacity, and low calorific value. Its special internal structure improves thermal efficiency and prevents sticking and over-drying of the sludge.

Efficient Drying: Capable of drying materials with up to 90% water content in a single operation.

Special Design: Prevents common issues like sticking and over-drying.

Versatile Application: Can handle various high-viscosity materials, not just sludge.

Modified Plate Structure: Adapts the general single-channel dryer’s material plate structure.

Self-Cleaning Device: Helps manage agglomeration during drying, expanding the dryer’s application range.

Both the rotary dryer and sludge dryer from Henan Terbaik Machinery offer efficient, reliable, and versatile drying solutions tailored to various industrial needs.

Advantages of Rotary Dryer

Efficient Preheating:

The sludge is preheated and partially dried as it falls through the high-temperature air stream inside the dryer.

This initial preheating reduces the moisture content and prepares the sludge for further drying.

Enhanced Heat Transfer:

The sludge is lifted and scattered multiple times by the inclined lifting plates and wing plates.

This repeated lifting and scattering ensures thorough convection and contact heat exchange between the sludge and the hot air, leading to efficient drying.

Self-Cleaning Mechanism:

A cleaning device within the dryer continually cleans the material adhering to the inner and outer walls of the lifting plates.

This mechanism prevents buildup and ensures consistent drying performance.

Effective Drying of High-Viscosity Materials:

The rotary dryer is specially designed to handle high-viscosity materials, like sludge, preventing sticking and over-drying.

It can dry materials with up to 90% water content to a low-moisture, loose final product in one pass.

Increased Drying Speed:

The integrated cleaning device helps break up sludge pellets, further enhancing the drying speed.

This leads to a more efficient drying process and reduces the time needed to achieve the desired moisture content.

Energy Efficiency:

The use of a new transmission device reduces energy consumption, saving nearly 20% in coal use compared to general sludge dryers.

This contributes to lower operational costs and increased value for customers.

Environmental Compliance:

The dryer is equipped with multi-stage purification and dust removal systems.

It meets and exceeds national environmental protection standards, minimizing environmental pollution.

By combining these advantages, the rotary dryer from Henan Terbaik Machinery provides an efficient, reliable, and environmentally friendly solution for drying high-moisture, high-viscosity materials like sludge.

Convenient transportation, crawler walking, no damage to the road, equipped with multi-functional accessories, Drived by oil and electricity.

The whole crushing plant adopts all-wheel drive to realize rotating direction in place, with perfect protection function, especially suitable for narrow and complex site.

The crawler crushing plant could be optional for jaw crusher, impatct crusher, cone crusher, VSI crusher etc.

Working Principle of Rotary Dryer

The rotary dryer operates as follows:

Feeding: The sludge enters the dryer from the feeder via a chute.

Initial Preheating: As the cylinder rotates, the sludge is guided to an inclined lifting plate. It is then lifted to the center of the cylinder and gradually falls to form a material curtain. High-temperature air flows through this curtain, preheating the sludge and evaporating some of its moisture.

Heat Transfer: When the sludge reaches the movable grate wing, it mixes with the preheated wing. This process transfers heat to the sludge, causing more moisture to evaporate.

Lifting and Scattering: The wing plate lifts and scatters the sludge repeatedly. This repeated action enables convection and contact heat exchange between the material and the hot air flow.

Cleaning: A cleaning device inside the dryer slides down the inner side of the arc-shaped lifting plate, cleaning material that adheres to the inner wall. It also cleans the outer wall of the lifting plate when dragged on the back of the arc hoisting plate.

Drying: As the cylinder continuously rotates, more water evaporates from the sludge, further drying it. The cleaning device also breaks up sludge pellets, increasing the drying speed.

Discharge: The now-dried, loose material with low moisture content is discharged from the outlet.

High Efficiency and Energy Saving:

Utilizes a new transmission device, reducing coal consumption by nearly 20% compared to general sludge dryers.

Lowers operating costs and adds value for customers.

Green Environmental Protection:

Equipped with multi-stage purification and dust removal equipment.

Meets and exceeds national environmental protection standards.

Minimizes the pollution of the equipment to the environment.

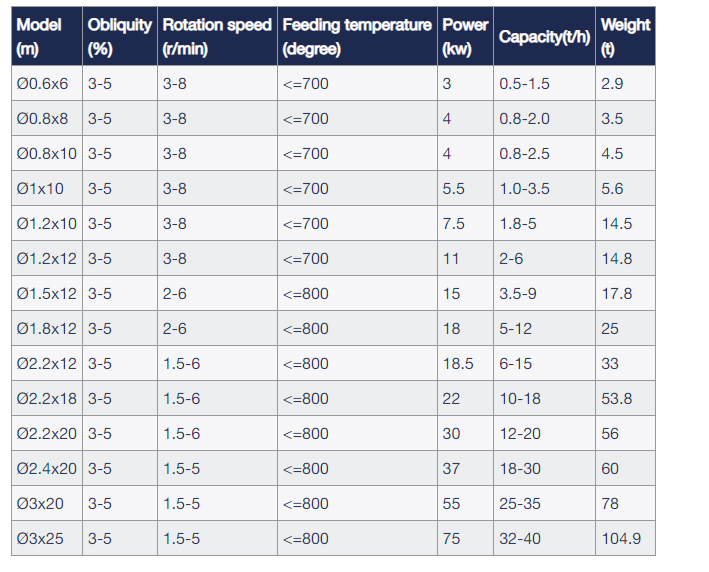

Specification Rotary Dryer

*The output will vary according to different materials, feed particle size and other factors