Terbaikmachinery offers high-performance vibrating screens designed for efficient material screening in mining. Our vibrating screens utilize advanced technology to ensure thorough and accurate particle separation, enhancing productivity and product quality. Trust Terbaikmachinery for expertly crafted screening solutions that deliver optimal performance and reliability.

YK series vibrating screen is a high-efficiency vibrating screening equipment that uses an inner eccentric shaft or block eccentricity as the excitation force. It has the advantages of a stable structure, high screening efficiency, low power consumption, and low noise. It is widely used in product grading and screening operations in many industries.

YK series vibrating screens are widely used in quarrying sand and gravel, as well as product grading in coal preparation, mineral processing, building materials, power, and chemical industries. Its efficient and stable screening performance has been recognized by the majority of users.

YK1545 type of vibrating screen is suitable for screening small and medium-sized materials. YK1860 performs well when processing large amounts of materials; the YK2160 vibrating screen is widely praised for its powerful processing capacity and efficient screening performance; YK2460, as a large vibrating screen in the YK series, has significant advantages in screening large materials.

Here’s a refined overview of the advantages of a circular vibrating screen:

Advantages of YK series vibrating screens

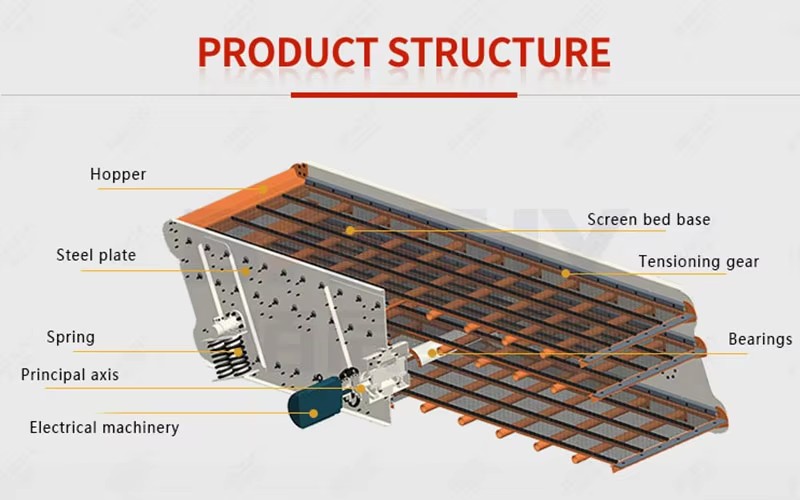

Efficient screening mechanism: YK series vibrating screens use internal eccentric shafts or block eccentricity as excitation force, and the eccentric shaft or eccentric block is driven by the motor to rotate so that the vibrating screen moves in a circular trajectory of up, forward, and down and backward. This motion trajectory allows the screened material to slip through the screen evenly and quickly, thereby improving the screening efficiency.

Multiple screening specifications: The mesh size of the YK series vibrating screen is generally between 3-50mm, which can be adjusted according to the screening requirements of different materials. At the same time, its processing capacity can reach 250t/h, ensuring efficient screening without blocking holes.

Convenient transportation, crawler walking, no damage to the road, equipped with multi-functional accessories, Drived by oil and electricity.

The whole crushing plant adopts all-wheel drive to realize rotating direction in place, with perfect protection function, especially suitable for narrow and complex site.

The crawler crushing plant could be optional for jaw crusher, impatct crusher, cone crusher, VSI crusher etc.

Working principle of Vibrating Screen

The electromotor drives the belt and pulley to make the movable jaw move back and forth, up and down through the eccentric shaft. The raw material is squashed or splitt when movable jaw plate moves towards fixed jaw together with movable jaw. When movable jaw and movable jaw plate turn back by eccentric shaft and spring, the raw material, which is squashed or split before discharges from the bottom outlet under jaw plate. The bulk-production comes true while electromotor rotates continuously and the movable jaw crushes and discharges the raw material periodically.

| Model | Sieve layer | Sieve area (㎡) | Mesh size (mm) | Max. feeding size (mm) | Processing capacity (m³/h) | Vibrating Frequency (r/min) | Double amplitude (mm) | Motor power (kw) | Sieve obliquity (°) | Sieve specification (mm) | Total weight (kg) | Dimensions (L×W×H) (mm) |

| 2YK1225 | 2 | 6 | 4-50 | 400 | 8-60 | 800-970 | 8 | 5.5 | 20 | 1200×2500 | 3500 | 2930×1860×870 |

| 3YK1225 | 3 | 9 | 4-50 | 400 | 10-70 | 800-970 | 8 | 5.5 | 20 | 1200×2500 | 3850 | 3070×1860×1210 |

| 2YK1230 | 2 | 7.2 | 4-50 | 400 | 12-78 | 800-970 | 8 | 7.5 | 20 | 1200×3000 | 4200 | 3430×1860×870 |

| 3YK1230 | 3 | 10.8 | 4-50 | 400 | 13-80 | 800-970 | 8 | 7.5 | 20 | 1200×3700 | 4600 | 3570×1860×1210 |

| 2YK1237 | 2 | 8.88 | 4-50 | 400 | 15-86 | 800-970 | 8 | 7.5 | 20 | 1200×3700 | 4600 | 4050×1860×870 |

| 3YK1237 | 3 | 13.32 | 4-50 | 400 | 16-90 | 800-970 | 8 | 7.5 | 20 | 1500×3500 | 5200 | 4270×1860×1210 |

| 2YK1535 | 2 | 10.5 | 5-50 | 400 | 20-125 | 800-970 | 8 | 11 | 20 | 1500×3500 | 5890 | 4120×2210×1230 |

| 3YK1535 | 3 | 15.75 | 5-50 | 400 | 21-125 | 800-970 | 8 | 11 | 20 | 1500×3500 | 6700 | 4360×2210×1610 |

| 2YK1545 | 2 | 13.5 | 5-50 | 400 | 22-150 | 800-970 | 8 | 15 | 20 | 1500×4500 | 6330 | 5120×2210×1230 |

| 3YK1545 | 3 | 20.25 | 5-50 | 400 | 22-150 | 800-970 | 8 | 15 | 20 | 1500×4500 | 6800 | 5360×2210×1610 |

| 4YK1545 | 4 | 27 | 5-50 | 400 | 22-155 | 800-970 | 8 | 18.5 | 20 | 1500×4500 | 7800 | 5930×2210×2060 |

| 2YK1548 | 2 | 14.4 | 5-50 | 400 | 22.5-162 | 800-970 | 8 | 15 | 20 | 1500×4800 | 6980 | 5420×2210×1230 |

| 3YK1548 | 3 | 21.6 | 5-50 | 400 | 22.5-162 | 800-970 | 11 | 15 | 20 | 1500×4800 | 7700 | 5660×2210×1610 |

| 4YK1548 | 4 | 28.8 | 5-50 | 400 | 22.5-162 | 800-970 | 8 | 18.5 | 20 | 1500×4800 | 8700 | 6230×2210×2060 |

| 2YK1848 | 2 | 17.28 | 5-80 | 400 | 25-206 | 750 | 8 | 15 | 20 | 1800×4800 | 9080 | 5420×2550×1420 |

| 3YK1848 | 3 | 25.92 | 5-80 | 400 | 32-276 | 750 | 8 | 18.5 | 20 | 1800×4800 | 9600 | 5660×2550×1780 |

| 4YK1848 | 4 | 34.56 | 5-80 | 400 | 32-285 | 750 | 8 | 22 | 20 | 1800×4800 | 11100 | 6290×2550×2160 |

| 2YK1854 | 2 | 19.44 | 5-80 | 400 | 32-312 | 800-970 | 8 | 18.5 | 20 | 1800×5400 | 10150 | 5960×2550×1420 |

| 3YK1854 | 3 | 29.16 | 5-80 | 400 | 32-312 | 800-970 | 8 | 22 | 20 | 1800×5400 | 10840 | 6260×2550×1780 |

| 4YK1854 | 4 | 38.88 | 5-80 | 400 | 32-336 | 800-970 | 8 | 30 | 20 | 1800×5400 | 12840 | 6830×2550×2160 |

| 2YK2160 | 2 | 25.2 | 5-100 | 400 | 50-475 | 970 | 8 | 30 | 20 | 2100×2600 | 11780 | 6720×2840×1530 |

| 3YK2160 | 3 | 37.8 | 5-100 | 400 | 50-475 | 970 | 8 | 30 | 20 | 2100×2600 | 12800 | 7030×2840×1910 |

| 4YK2160 | 4 | 50.4 | 5-100 | 400 | 50-497 | 970 | 8 | 37 | 20 | 2100×2600 | 14800 | 7300×2840×2380 |

| 2YK2460 | 2 | 28.8 | 5-100 | 400 | 65-550 | 970 | 8 | 37 | 20 | 2400×6000 | 15600 | 7020×3140×1530 |

| 3YK2460 | 3 | 43.2 | 5-100 | 400 | 70-620 | 970 | 8 | 37 | 20 | 2400×6000 | 17600 | 7300×3140×1910 |

| 4YK2460 | 4 | 57.6 | 5-100 | 400 | 80-680 | 970 | 8 | 45 | 20 | 2400×6000 | 19600 | 7600×3140×2380 |

| 2YK2870 | 2 | 39.2 | 5-100 | 400 | 120-680 | 750 | 8 | 22×2 | 20 | 2800×7000 | 21200 | 7600×4320×1620 |

| 3YK2870 | 3 | 58.8 | 5-100 | 400 | 180-720 | 750 | 8 | 22×2 | 20 | 2800×7000 | 22400 | 7800×4320×2120 |

| 2YK3072 | 2 | 43.2 | 5-100 | 400 | 200-700 | 750 | 8 | 22×2 | 20 | 3000×7200 | 23600 | 7800×4520×1750 |

| 3YK3072 | 3 | 64.8 | 5-100 | 400 | 230-800 | 750 | 8 | 22×2 | 20 | 3000×7200 | 25500 | 8000×4520×2300 |

About YK Series vibrating screen

YK series vibrating screens generally have a large processing capacity and can meet the needs of production lines of different sizes.

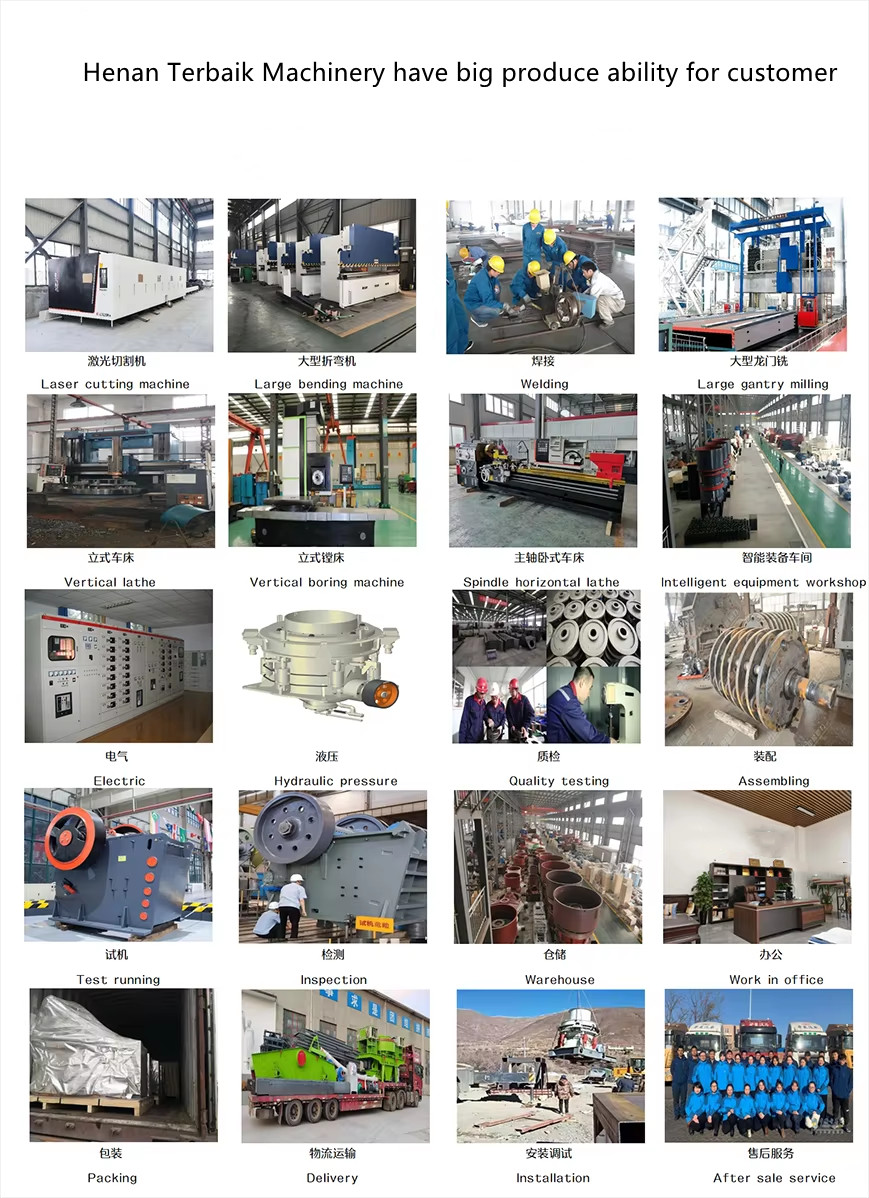

About delivery standards

Terbaik machinery has extremely complete delivery standards, a series of standards and regulations formulated to ensure that the ordered goods can be delivered completely and accurately according to the needs and requirements of customers. These standards usually involve quantity, specifications, quality, packaging, documents and time, etc., to ensure the smooth progress of the delivery process and improve customer satisfaction.

If you needs others stone crusher , it is also avaiable

FAQ:

Q:Are you manufacture or trading company?

A: We are factory.

Q: How long is your delivery time?

A:7-10 days for the stock.15-30 days for the mass production.

Q:What is your payment method?

A:30% deposit in TT advance, 70% balance before shipment.

Q: How long is the warranty? Does your company supply the spare parts?

A:One year. Spare parts for you at lowest cost.

Q: lf l need the complete crushing plant can you help us to build it?

A:Yes, we can help you set up a complete production line and give you related professional advice. Wehad already build many mining projects in China & Overseas.

*The output will vary according to different materials, feed particle size and other factors